Page 328 - THREADING CATALOG

P. 328

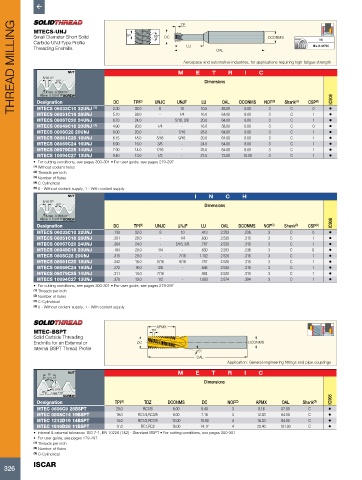

THREAD MILLING MTECS-UNJ NUT TP 60° DC M Aerospace and automotive industries, for applications requiring high fatigue strength

TP

Small Diameter Short Solid

DCONMS

3B

Carbide UNJ-Type Profile

LU

MIL-S-8879C

Threading Endmills

OAL

I

C

R

T

E

5/16 TP

60°

Dimensions

REmax 0.18042TP

REmin 0.15011TPSCREW

UNJF

LU

OAL

Designation

DC

MTECS 06033C10 32UNJ

10

8

6.00

32.0

3

0

C

•

C

1

64.00

28.0

16.0

1/4

MTECS 08051C16 28UNJ

8.00

-

5.10

3

•

MTECS 08067C20 24UNJ (1) 3.30 TPI (2) UNJC 5/16, 3/8 10.5 58.00 DCONMS NOF (3) Shank (4) CSP (5) • IC908

6.70

24.0

3

-

8.00

C

20.0

1

64.00

MTECS 06049C16 20UNJ (1) 4.90 20.0 1/4 - 16.0 58.00 6.00 3 C 0 •

MTECS 0808C28 20UNJ 8.00 20.0 - 7/16 28.0 64.00 8.00 3 C 1 •

MTECS 08061C20 18UNJ 6.15 18.0 5/16 9/16 20.0 64.00 8.00 3 C 1 •

MTECS 08069C24 16UNJ 6.90 16.0 3/8 - 24.0 64.00 8.00 3 C 1 •

MTECS 08079C25 14UNJ 7.90 14.0 7/16 - 25.0 64.00 8.00 3 C 1 •

MTECS 10094C27 13UNJ 9.40 13.0 1/2 - 27.5 73.00 10.00 3 C 1 •

• For cutting conditions, see pages 300-301 • For user guide, see pages 279-297

(1) Without coolant holes

(2) Threads per inch

(3) Number of flutes

(4) C-Cylindrical

(5) 0 - Without coolant supply, 1 - With coolant supply

NUT I N C H

5/16 TP

60° Dimensions

REmax 0.18042TP

REmin 0.15011TPSCREW

Designation DC TPI (1) UNJC UNJF LU OAL DCONMS NOF (2) Shank (3) CSP (4) IC908

MTECS 06033C10 32UNJ .130 32.0 8 10 .413 2.283 .236 3 C 0 •

MTECS 08051C16 28UNJ .201 28.0 - 1/4 .630 2.520 .315 3 C 1 •

MTECS 08067C20 24UNJ .264 24.0 - 5/16, 3/8 .787 2.520 .315 3 C 1 •

MTECS 06049C16 20UNJ .193 20.0 1/4 - .630 2.283 .236 3 C 0 •

MTECS 0808C28 20UNJ .315 20.0 - 7/16 1.102 2.520 .315 3 C 1 •

MTECS 08061C20 18UNJ .242 18.0 5/16 9/16 .787 2.520 .315 3 C 1 •

MTECS 08069C24 16UNJ .272 16.0 3/8 - .945 2.520 .315 3 C 1 •

MTECS 08079C25 14UNJ .311 14.0 7/16 - .984 2.520 .315 3 C 1 •

MTECS 10094C27 13UNJ .370 13.0 1/2 - 1.083 2.874 .394 3 C 1 •

• For cutting conditions, see pages 300-301 • For user guide, see pages 279-297

(1) Threads per inch

(2) Number of flutes

(3) C-Cylindrical

(4) 0 - Without coolant supply, 1 - With coolant supply

APMX

MTEC-BSPT TP

Solid Carbide Threading

Endmills for an External or DC DCONMS

Internal BSPT Thread Profile

15°

OAL

Application: General engineering fittings and pipe couplings

NUT M E T R I C

TP

27.5˚ 27.5˚

Dimensions

RE=0.137TP

90˚ Taper 1:16

SCREW

Designation TPI (1) TDZ DCONMS DC NOF (2) APMX OAL Shank (3) IC908

MTEC 0606C9 28BSPT 28.0 RC1/8 6.00 5.40 3 8.16 57.00 C •

MTEC 0808C14 19BSPT 19.0 RC1/4,RC3/8 8.00 7.16 3 12.03 64.00 C •

MTEC 1212D19 14BSPT 14.0 RC1/2,RC7/8 12.00 10.88 4 16.33 84.00 C •

MTEC 1616D28 11BSPT 11.0 RC1,RC2 16.00 14.17 4 25.40 101.00 C •

• internal & external tolerance: ISO 7-1, EN 10226 (1&2) - Standard BSPT • For cutting conditions, see pages 300-301

• For user guide, see pages 279-297

(1) Threads per inch

(2) Number of flutes

(3) C-Cylindrical

ISCAR

326