Page 330 - THREADING CATALOG

P. 330

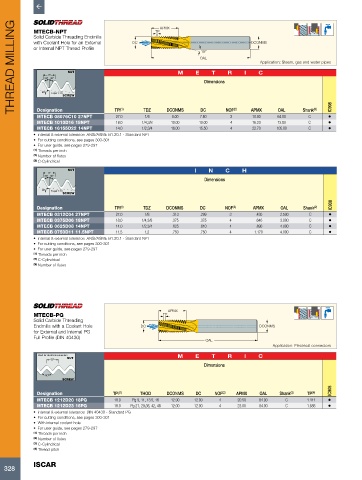

THREAD MILLING MTECB-NPT NUT DC TP APMX M E OAL Dimensions R I DCONMS

Solid Carbide Threading Endmills

with Coolant Hole for an External

or Internal NPT Thread Profile

15°

Application: Steam, gas and water pipes

C

T

TP

30˚

30˚

90˚

Taper 1:16

SCREW

DC

Designation

OAL

MTECB 08076C10 27NPT TPI (1) TDZ DCONMS 7.60 NOF (2) APMX 64.00 Shank (3) • IC908

8.00

27.0

1/8

10.80

C

3

MTECB 1010D16 18NPT 18.0 1/4,3/8 10.00 10.00 4 16.20 73.00 C •

MTECB 16155D22 14NPT 14.0 1/2,3/4 16.00 15.50 4 22.70 105.00 C •

• internal & external tolerance: ANSI/ASME B1.20.1 - Standard NPT

• For cutting conditions, see pages 300-301

• For user guide, see pages 279-297

(1) Threads per inch

(2) Number of flutes

(3) C-Cylindrical

NUT I N C H

TP

30˚ 30˚

Dimensions

90˚ Taper 1:16

SCREW

IC908

Designation TPI (1) TDZ DCONMS DC NOF (3) APMX OAL Shank (2)

MTECB 0312C04 27NPT 27.0 1/8 .313 .299 3 .430 2.500 C •

MTECB 0375D06 18NPT 18.0 1/4,3/8 .375 .375 4 .640 3.000 C •

MTECB 0625D08 14NPT 14.0 1/2,3/4 .625 .610 4 .890 4.000 C •

MTECB 0750D11 11.5NPT 11.5 1,2 .750 .750 4 1.170 4.000 C •

• internal & external tolerance: ANSI/ASME B1.20.1 - Standard NPT

• For cutting conditions, see pages 300-301

• For user guide, see pages 279-297

(1) Threads per inch

(2) C-Cylindrical

(3) Number of flutes

MTECB-PG TP APMX

Solid Carbide Threading

Endmills with a Coolant Hole DC DCONMS

for External and Internal PG

Full Profile (DIN 40430)

OAL

Application: Electrical connectors

Used for electrical connectors M E T R I C

NUT

TP

Dimensions

80˚

SCREW

IC908

Designation TPI (1) THOD DCONMS DC NOF (2) APMX OAL Shank (3) TP (4)

MTECB 1212D20 18PG 18.0 Pg 9, 11, 13.5, 16 12.00 12.00 4 20.50 84.00 C 1.411 •

MTECB 1212D23 16PG 16.0 Pg 21, 29,36, 42, 48 12.00 12.00 4 23.00 84.00 C 1.588 •

• internal & external tolerance: DIN 40430 - Standard PG

• For cutting conditions, see pages 300-301

• With internal coolant hole

• For user guide, see pages 279-297

(1) Threads per inch

(2) Number of flutes

(3) C-Cylindrical

(4) Thread pitch

ISCAR

328