Page 169 - THREADING CATALOG

P. 169

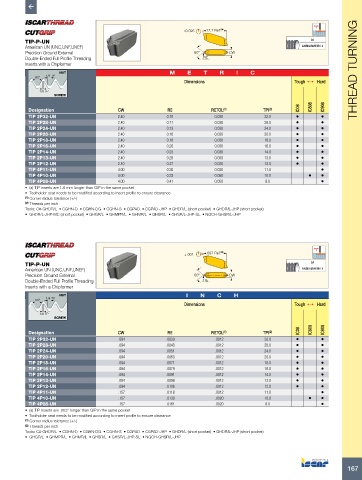

±0.025 17.7 Ref. (a)

TIP-P-UN 2A

American UN (UNC,UNF,UNEF) ANSI/ASME B1.1

Precision Ground External 60° CW

Double-Ended Full Profile Threading RE

Inserts with a Chipformer

NUT M E T R I C THREAD TURNING

1/4 TP

60°

Dimensions Tough 1 Hard

1/8 TP

SCREW

Designation CW RE RETOL (1) TPI (2) IC08 IC808 IC908

TIP 2P32-UN 2.40 0.10 0.030 32.0 • •

TIP 2P28-UN 2.40 0.11 0.030 28.0 • •

TIP 2P24-UN 2.40 0.13 0.030 24.0 • •

TIP 2P20-UN 2.40 0.16 0.030 20.0 • •

TIP 2P18-UN 2.40 0.18 0.030 18.0 • •

TIP 2P16-UN 2.40 0.20 0.030 16.0 • •

TIP 2P14-UN 2.40 0.23 0.030 14.0 • •

TIP 2P13-UN 2.40 0.25 0.030 13.0 • •

TIP 2P12-UN 2.40 0.27 0.030 12.0 • •

TIP 4P11-UN 4.00 0.30 0.030 11.0 •

TIP 4P10-UN 4.00 0.33 0.050 10.0 • •

TIP 4P08-UN 4.00 0.41 0.050 8.0 •

• (a) TIP inserts are 1.6 mm longer than GIP in the same pocket

• Toolholder seat needs to be modified according to insert profile to ensure clearance

(1) Corner radius tolerance (+/-)

(2) Threads per inch

Tools: C#-GHDR/L • CGHN-D • CGHN-DG • CGHN-S • CGPAD • CGPAD-JHP • GHDR/L (short pocket) • GHDR/L-JHP (short pocket)

• GHDR/L-JHP-MC (short pocket) • GHGR/L • GHMPR/L • GHMR/L • GHSR/L • GHSR/L-JHP-SL • NQCH-GHSR/L-JHP

±.001 .697 Ref. (a)

TIP-P-UN 2A

American UN (UNC,UNF,UNEF) ANSI/ASME B1.1

Precision Ground External 60° CW

Double-Ended Full Profile Threading RE

Inserts with a Chipformer

NUT I N C H

1/4 TP

60°

Dimensions Tough 1 Hard

1/8 TP

SCREW

Designation CW RE RETOL (1) TPI (2) IC08 IC808 IC908

TIP 2P32-UN .094 .0039 .0012 32.0 • •

TIP 2P28-UN .094 .0043 .0012 28.0 • •

TIP 2P24-UN .094 .0051 .0012 24.0 • •

TIP 2P20-UN .094 .0063 .0012 20.0 • •

TIP 2P18-UN .094 .0071 .0012 18.0 • •

TIP 2P16-UN .094 .0079 .0012 16.0 • •

TIP 2P14-UN .094 .0091 .0012 14.0 • •

TIP 2P13-UN .094 .0098 .0012 13.0 • •

TIP 2P12-UN .094 .0106 .0012 12.0 • •

TIP 4P11-UN .157 .0118 .0012 11.0 •

TIP 4P10-UN .157 .0130 .0020 10.0 • •

TIP 4P08-UN .157 .0161 .0020 8.0 •

• (a) TIP inserts are .063" longer than GIP in the same pocket

• Toolholder seat needs to be modified according to insert profile to ensure clearance

(1) Corner radius tolerance (+/-)

(2) Threads per inch

Tools: C#-GHDR/L • CGHN-D • CGHN-DG • CGHN-S • CGPAD • CGPAD-JHP • GHDR/L (short pocket) • GHDR/L-JHP (short pocket)

• GHGR/L • GHMPR/L • GHMR/L • GHSR/L • GHSR/L-JHP-SL • NQCH-GHSR/L-JHP

167