Page 167 - THREADING CATALOG

P. 167

Continued

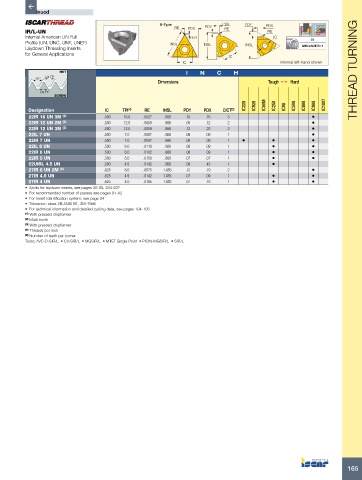

U-Type PDX PDY PDX

IR/L-UN RE PDX PDY RE RE

Internal American UN Full PDY IC 2B

Profile (UN, UNC, UNF, UNEF) lNSL lNSL lNSL

Laydown Threading Inserts ANSI/ASME B1.1

for General Applications IC

IC Internal left-hand shown

NUT I N C H THREAD TURNING

1/4 TP

60°

Dimensions Tough 1 Hard

1/8 TP

SCREW

IC228 IC928 IC50M IC250 IC08 IC508 IC808 IC908 IC1007

Designation IC TPI (4) RE INSL PDY PDX CICT (5)

22IR 16 UN 3M (2) .500 16.0 .0027 .866 .10 .16 3 •

22IR 12 UN 2M (2) .500 12.0 .0059 .866 .09 .12 2 •

22IR 12 UN 3M (2) .500 12.0 .0059 .866 .12 .20 3 •

22IL 7 UN .500 7.0 .0087 .866 .06 .09 1 •

22IR 7 UN .500 7.0 .0087 .866 .06 .09 1 • • •

22IL 6 UN .500 6.0 .0118 .866 .06 .09 1 • •

22IR 6 UN .500 6.0 .0102 .866 .06 .09 1 • •

22IR 5 UN .500 5.0 .0150 .866 .07 .07 1 • •

22UIRL 4.5 UN .500 4.5 .0142 .866 .09 .43 1 •

27IR 8 UN 2M (2) .625 8.0 .0075 1.083 .12 .19 2 •

27IR 4.5 UN .625 4.5 .0142 1.083 .07 .09 1 • •

27IR 4 UN .625 4.0 .0185 1.083 .07 .10 1 • •

• Anvils for laydown inserts, see pages 26-35, 234-237

• For recommended number of passes see pages 81-82

• For Insert Identification system, see page 24

• Tolerance: class 2B,ANSI B1, 3M-1986

• For technical information and detailed cutting data, see pages 104-105

(1) With pressed chipformer

(2) Multi-tooth

(3) With pressed chipformer

(4) Threads per inch

(5) Number of teeth per corner

Tools: AVC-D-SIR/L • C#-SIR/L • MGSIR/L • MTET Single Point • PICIN-MGSIR/L • SIR/L

165