Page 150 - THREADING CATALOG

P. 150

Continued U-Type RE PDX PDY RE PDY PDX IC 6H

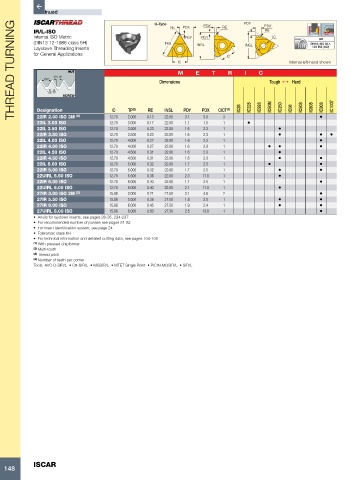

THREAD TURNING (DIN13 12-1986 class 6H) Dimensions IC E INSL T IC R I INSL C Tough 1 Hard DIN13, ISO 68-1,

PDX

RE

IR/L-ISO

Internal ISO Metric

PDY

INSL

ISO 965 (1&2)

Laydown Threading Inserts

for General Applications

Internal left-hand shown

NUT

M

1/4 TP

60°

1/8 TP

SCREW

(3)

TP

IC

Designation

RE

3

3.1

5.0

22IR 2.00 ISO 3M

22.00

0.17

22.00

22IL 3.00 ISO (2) 12.70 2.000 0.13 INSL PDY PDX CICT (4) IC28 • IC228 IC928 IC50M IC250 IC08 IC508 IC808 • IC908 IC1007

1.1

1.5

1

12.70

3.000

22IL 3.50 ISO 12.70 3.500 0.23 22.00 1.6 2.3 1 •

22IR 3.50 ISO 12.70 3.500 0.23 22.00 1.6 2.3 1 • • •

22IL 4.00 ISO 12.70 4.000 0.27 22.00 1.6 2.3 1 •

22IR 4.00 ISO 12.70 4.000 0.27 22.00 1.6 2.3 1 • • •

22IL 4.50 ISO 12.70 4.500 0.31 22.00 1.6 2.3 1 •

22IR 4.50 ISO 12.70 4.500 0.31 22.00 1.6 2.3 1 • •

22IL 5.00 ISO 12.70 5.000 0.32 22.00 1.7 2.5 1 • •

22IR 5.00 ISO 12.70 5.000 0.32 22.00 1.7 2.5 1 • •

22UIRL 5.50 ISO 12.70 5.500 0.36 22.00 2.3 11.0 1 •

22IR 6.00 ISO 12.70 6.000 0.40 22.00 1.7 2.5 1 •

22UIRL 6.00 ISO 12.70 6.000 0.40 22.00 2.1 11.0 1 •

27IR 3.00 ISO 2M (2) 15.88 3.000 0.21 27.50 3.1 4.6 2 •

27IR 5.50 ISO 15.88 5.500 0.36 27.50 1.8 2.5 1 • •

27IR 6.00 ISO 15.88 6.000 0.45 27.50 1.9 2.4 1 • •

27UIRL 8.00 ISO 15.88 8.000 0.50 27.50 2.5 13.8 1 •

• Anvils for laydown inserts, see pages 26-35, 234-237

• For recommended number of passes see pages 81-82

• For Insert Identification system, see page 24

• Tolerance: class 6H

• For technical information and detailed cutting data, see pages 104-105

(1) With pressed chipformer

(2) Multi-tooth

(3) Thread pitch

(4) Number of teeth per corner

Tools: AVC-D-SIR/L • C#-SIR/L • MGSIR/L • MTET Single Point • PICIN-MGSIR/L • SIR/L

ISCAR

148