Page 117 - THREADING CATALOG

P. 117

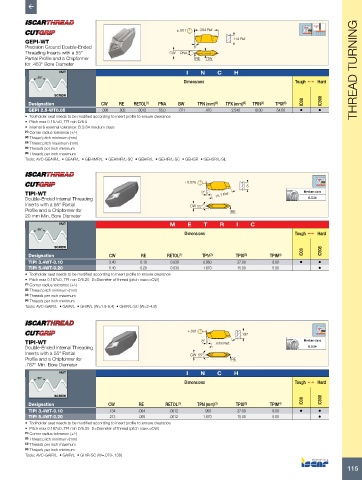

±.001 .394 Ref.

GEPI-WT .114 Ref.

Precision Ground Double-Ended 8˚

Threading Inserts with a 55° CW PNA

Partial Profile and a Chipformer RE BW

for .453" Bore Diameter

NUT I N C H THREAD TURNING

55°

Dimensions Tough 1 Hard

SCREW

Designation CW RE RETOL (1) PNA BW TPN (mm) (2) TPX (mm) (3) TPIN (4) TPIX (5) IC08 IC908

GEPI 2.5-WT0.05 .098 .002 .0012 55.0 .071 .470 2.540 10.00 54.00 • •

• Toolholder seat needs to be modified according to insert profile to ensure clearance

• Pitch max 0.167xD, TPI min D/6.0

• internal & external tolerance: B.S.84 medium class

(1) Corner radius tolerance (+/-)

(2) Thread pitch minimum (mm)

(3) Thread pitch maximum (mm)

(4) Threads per inch minimum

(5) Threads per inch maximum

Tools: AVC-GEAIR/L • GEAIR/L • GEHIMR/L • GEHIMR/L-SC • GEHIR/L • GEHIR/L-SC • GEHSR • GEHSR/L-SL

±0.025 5

TIPI-WT 8° 15.7 Ref. Medium class

Double-Ended Internal Threading B.S.84

Inserts with a 55° Partial CW 55°

Profile and a Chipformer for RE

20 mm Min. Bore Diameter

NUT M E T R I C

55°

Dimensions Tough 1 Hard

SCREW

Designation CW RE RETOL (1) TPN (2) TPIX (3) TPIN (4) IC08 IC908

TIPI 3.4WT-0.10 3.40 0.10 0.030 0.950 27.00 8.00 • •

TIPI 5.4WT-0.20 5.40 0.20 0.030 1.670 15.00 5.00 •

• Toolholder seat needs to be modified according to insert profile to ensure clearance

• Pitch max 0.187xD, TPI min D/5.25 D=Diameter of thread (pitch max<=CW)

(1) Corner radius tolerance (+/-)

(2) Thread pitch minimum (mm)

(3) Threads per inch maximum

(4) Threads per inch minimum

Tools: AVC-GAIR/L • GAIR/L • GHIR/L (W=1.9-6.4) • GHIR/L-SC (W=2-4.8)

±.001 .197

TIPI-WT 8° .618 Ref. Medium class

Double-Ended Internal Threading B.S.84

Inserts with a 55° Partial CW 55°

Profile and a Chipformer for RE

.787" Min. Bore Diameter

NUT I N C H

55°

Dimensions Tough 1 Hard

SCREW

Designation CW RE RETOL (1) TPN (mm) (2) TPIX (3) TPIN (4) IC08 IC908

TIPI 3.4WT-0.10 .134 .004 .0012 .950 27.00 8.00 • •

TIPI 5.4WT-0.20 .213 .008 .0012 1.670 15.00 5.00 •

• Toolholder seat needs to be modified according to insert profile to ensure clearance

• Pitch max 0.187xD, TPI min D/5.25 D=Diameter of thread (pitch max<=CW)

(1) Corner radius tolerance (+/-)

(2) Thread pitch minimum (mm)

(3) Threads per inch maximum

(4) Threads per inch minimum

Tools: AVC-GAIR/L • GAIR/L • GHIR-SC (W=.079-.138)

115