Page 99 - ISCAR FACE GROOVING LINES

P. 99

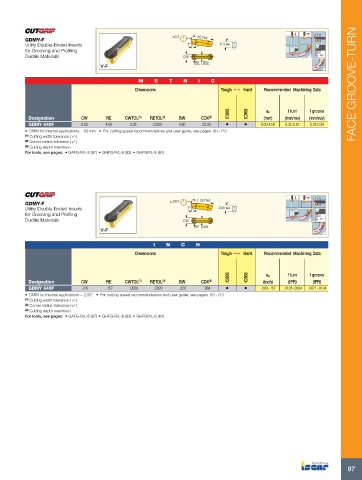

GDMY-F ±0.1 30 Ref. 6.3 Ref. IC808

Utility Double-Ended Inserts 7º IC908

for Grooving and Profiling

Ductile Materials CW FACE GROOVE-TURN

RE BW

METRIC

Dimensions Tough 1 Hard Recommended Machining Data

ap f turn f groove

Designation CW RE CWTOL(1) RETOL(2) BW CDX(3) (mm) (mm/rev) (mm/rev)

GDMY 840F 8.00 4.00 0.05 0.050 5.60 25.00 • •

0.00-4.00 0.32-0.67 0.18-0.34

• DMIN for internal applications = 65 mm • For cutting speed recommendations and user guide, see pages 161-173

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: • GAFG-R/L-8 (87) • GHFG-R/L-8 (83) • GHFGR/L-8 (84)

GDMY-F ±.004 1.18 Ref.

Utility Double-Ended Inserts 7º

for Grooving and Profiling .248 Ref.

Ductile Materials

CW

RE BW

INCH Tough 1 Hard Recommended Machining Data

Dimensions

Designation CW RE CWTOL(1) RETOL(2) BW CDX(3) IC808 ap f turn f groove

GDMY 840F IC908 (inch) (IPR) (IPR)

.315 .157 .0020 .0020 .220 .984 • • .000-.157 .0126-.0264 .0071-.0134

• DMIN for internal applications = 2.56" • For cutting speed recommendations and user guide, see pages 161-173

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: • GAFG-R/L-8 (87) • GHFG-R/L-8 (83) • GHFGR/L-8 (84)

97