Page 95 - ISCAR FACE GROOVING LINES

P. 95

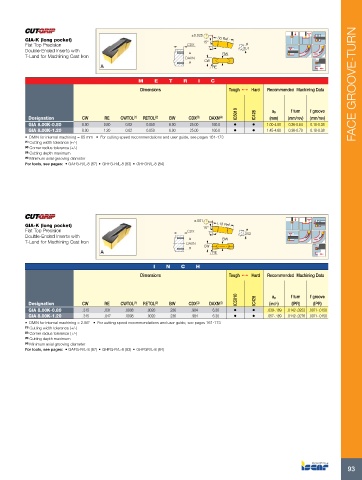

GIA-K (long pocket) ±0.025 30 Ref. IC5010

Flat Top Precision IC428

Double-Ended Inserts with CDX 15° 6.4

T-Land for Machining Cast Iron 7° FACE GROOVE-TURN

DAXN BW

CW

RE

ME T RIC

Dimensions

Tough 1 Hard Recommended Machining Data

Designation CW RE CWTOL(1) RETOL(2) BW CDX(3) DAXN(4) • ap f turn f groove

• (mm) (mm/rev) (mm/rev)

GIA 8.00K-0.80 8.00 0.80 0.02 0.050 6.00 25.00 160.0

GIA 8.00K-1.20 • 1.00-4.80 0.36-0.64 0.18-0.38

8.00 1.20 0.02 0.050 6.00 25.00 160.0 • 1.45-4.80 0.36-0.70 0.18-0.38

• DMIN for internal machining = 65 mm • For cutting speed recommendations and user guide, see pages 161-173

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

(4) Minimum axial grooving diameter

For tools, see pages: • GAFG-R/L-8 (87) • GHFG-R/L-8 (83) • GHFGR/L-8 (84)

GIA-K (long pocket) ±.001 1.18 Ref.

Flat Top Precision

Double-Ended Inserts with CDX 15° .252

T-Land for Machining Cast Iron 7°

BW

DAXN CW

RE

IN CH

Dimensions

Tough 1 Hard Recommended Machining Data

Designation CW RE CWTOL(1) RETOL(2) BW CDX(3) DAXN(4) IC5010 ap f turn f groove

IC428 (inch) (IPR) (IPR)

GIA 8.00K-0.80 .315 .031 .0008 .0020 .236 .984 6.30 • • .039-.189 .0142-.0252 .0071-.0150

GIA 8.00K-1.20 • • .057-.189 .0142-.0276 .0071-.0150

.315 .047 .0008 .0020 .236 .984 6.30

• DMIN for internal machining = 2.56" • For cutting speed recommendations and user guide, see pages 161-173

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

(4) Minimum axial grooving diameter

For tools, see pages: • GAFG-R/L-8 (87) • GHFG-R/L-8 (83) • GHFGR/L-8 (84)

93