Page 36 - ISCAR FACE GROOVING LINES

P. 36

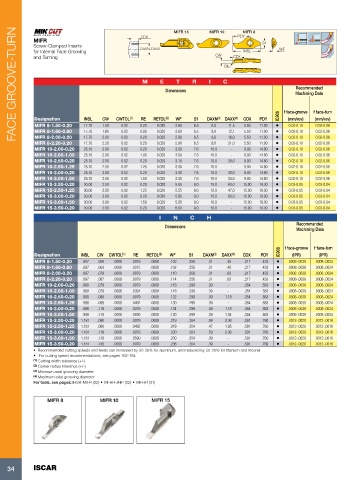

FACE GROOVE-TURN MIFR 15 MIFR 10 MIFR 8

PDY

MIFR CDX

Screw-Clamped Inserts DAXN-DAXX S1

for Internal Face Grooving

and Turning INSL WF

CW CDX

Recommended

RE Machining Data

METR IC

Dimensions

IC908 f face-groove f face-turn

Designation INSL CW CWTOL(1) RE RETOL(2) WF S1 DAXN(3) DAXX(4) CDX PDY (mm/rev) (mm/rev)

MIFR 8-1.50-0.20 17.70 1.50 0.02 0.20 0.020 2.60 6.5 8.0 11.5 5.50 11.00 • 0.02-0.10 0.02-0.06

MIFR 8-1.60-0.80 17.70 1.60 0.02 0.80 0.020 2.60 6.5 8.0 12.1 5.50 11.00 • 0.02-0.10 0.02-0.06

MIFR 8-2.00-0.20 17.70 2.00 0.02 0.20 0.020 2.80 6.5 8.0 16.0 5.50 11.00 • 0.02-0.10 0.02-0.06

MIFR 8-2.20-0.20 17.70 2.20 0.02 0.20 0.020 2.90 6.5 8.0 21.0 5.50 11.00 • 0.02-0.10 0.02-0.06

MIFR 10-2.00-0.20 25.10 2.00 0.02 0.20 0.020 3.00 7.6 10.0 9.00 14.80 • 0.02-0.10 0.02-0.06

MIFR 10-2.00-1.00 25.10 2.00 0.02 1.00 0.020 3.00 7.6 10.0 - 9.00 14.80 • 0.02-0.10 0.02-0.06

MIFR 10-2.50-0.20 25.10 2.50 0.02 0.20 0.020 3.10 7.6 10.0 - 9.00 14.80 • 0.02-0.10 0.02-0.06

MIFR 10-2.50-1.25 25.10 2.50 0.02 1.25 0.020 3.30 7.6 10.0 30.0 9.00 14.80 • 0.02-0.10 0.02-0.06

MIFR 10-3.00-0.20 25.10 3.00 0.02 0.20 0.020 3.40 7.6 10.0 - 9.00 14.80 • 0.02-0.10 0.02-0.06

MIFR 10-3.00-1.50 25.10 3.00 0.02 1.50 0.020 3.30 7.6 10.0 30.0 9.00 14.80 • 0.02-0.10 0.02-0.06

MIFR 15-2.50-0.20 30.00 2.50 0.02 0.20 0.020 5.55 9.0 15.0 34.0 15.00 19.30 • 0.03-0.05 0.03-0.04

MIFR 15-2.50-1.25 30.00 2.50 0.02 1.25 0.020 5.55 9.0 12.0 60.0 15.00 19.30 • 0.03-0.05 0.03-0.04

MIFR 15-3.00-0.20 30.00 3.00 0.02 0.20 0.020 5.85 9.0 15.0 47.0 15.00 19.30 • 0.03-0.05 0.03-0.04

MIFR 15-3.00-1.50 30.00 3.00 0.02 1.50 0.020 5.85 9.0 10.0 60.0 15.00 19.30 • 0.03-0.05 0.03-0.04

MIFR 15-3.50-0.20 30.00 3.50 0.02 0.20 0.020 6.00 9.0 10.0 - 15.00 19.30 • 0.03-0.05 0.03-0.04

-

INC H

Dimensions Recommended

Machining Data

Designation INSL CW CWTOL(1) RE RETOL(2) WF S1 DAXN(3) DAXX(4) CDX PDY IC908 f face-groove f face-turn

(IPR) (IPR)

MIFR 8-1.50-0.20 .697 .059 .0008 .0079 .0008 .102 .256 .31 .45 .217 .433

• .0008-.0039 .0008-.0024

MIFR 8-1.60-0.80 .697 .063 .0008 .0315 .0008 .102 .256 .31 .48 .217 .433 • .0008-.0039 .0008-.0024

• .0008-.0039 .0008-.0024

MIFR 8-2.00-0.20 .697 .079 .0008 .0079 .0008 .110 .256 .31 .63 .217 .433 • .0008-.0039 .0008-.0024

• .0008-.0039 .0008-.0024

MIFR 8-2.20-0.20 .697 .087 .0008 .0079 .0008 .114 .256 .31 .83 .217 .433 • .0008-.0039 .0008-.0024

• .0008-.0039 .0008-.0024

MIFR 10-2.00-0.20 .988 .079 .0008 .0079 .0008 .118 .299 .39 - .354 .583 • .0008-.0039 .0008-.0024

• .0008-.0039 .0008-.0024

MIFR 10-2.00-1.00 .988 .079 .0008 .0394 .0008 .118 .299 .39 - .354 .583 • .0008-.0039 .0008-.0024

• .0012-.0020 .0012-.0016

MIFR 10-2.50-0.20 .988 .098 .0008 .0079 .0008 .122 .299 .39 1.18 .354 .583 • .0012-.0020 .0012-.0016

• .0012-.0020 .0012-.0016

MIFR 10-2.50-1.25 .988 .098 .0008 .0492 .0008 .130 .299 .39 - .354 .583 • .0012-.0020 .0012-.0016

• .0012-.0020 .0012-.0016

MIFR 10-3.00-0.20 .988 .118 .0008 .0079 .0008 .134 .299 .39 1.18 .354 .583

MIFR 10-3.00-1.50 .988 .118 .0008 .0590 .0008 .130 .299 .39 1.34 .354 .583

MIFR 15-2.50-0.20 1.181 .098 .0008 .0079 .0008 .219 .354 .59 2.36 .591 .760

MIFR 15-2.50-1.25 1.181 .098 .0008 .0492 .0008 .219 .354 .47 1.85 .591 .760

MIFR 15-3.00-0.20 1.181 .118 .0008 .0079 .0008 .230 .354 .59 2.36 .591 .760

MIFR 15-3.00-1.50 1.181 .118 .0008 .0590 .0008 .230 .354 .39 - .591 .760

MIFR 15-3.50-0.20 1.181 .138 .0008 .0079 .0008 .236 .354 .39 - .591 .760

• Recommended cutting speeds and feeds can increased by 20-30% for aluminum, and reduced by 20-30% for titanium and Inconel

• For cutting speed recommendations, see pages 162-164

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Minimum axial grooving diameter

(4) Maximum axial grooving diameter

For tools, see pages: IHSR-MIFR (32) • MFHR-JHP (32) • MIFHR (31)

34 ISCAR