Page 245 - THREADING CATALOG

P. 245

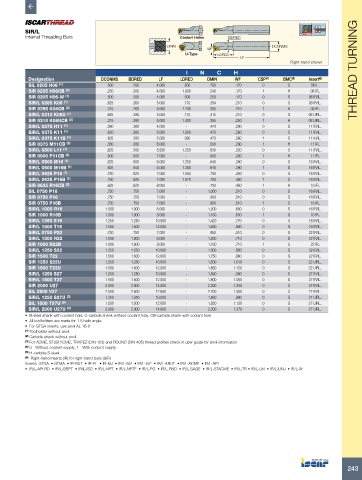

SIR/L

Internal Threading Bars Coolant Holes BDRED

DMIN DCONMS

WF

U-Type LDRED

LF

Right-hand shown

I N C H THREAD TURNING

Designation DCONMS BDRED LF LDRED DMIN WF CSP (4) BMC (5) Insert (6)

SIL 0205 H06 (1) .500 .200 4.000 .500 .250 .170 0 S 06 IL..

SIR 0205 H06CB (2) .250 .200 4.000 1.000 .240 .170 1 H 06 IR..

SIR 0205 H06-W (1) .500 .200 4.000 .500 .250 .170 0 S 06 IR/IL..

SIR/L 0265 K08 (1) .625 .260 5.000 .710 .354 .210 0 S 08 IR/IL..

SIR 0265 K08CB (2) .315 .260 5.000 1.200 .355 .210 1 H 08 IR..

SIR/L 0310 K08U (1) .625 .290 5.000 .710 .315 .210 0 S 08 UIRL..

SIR 0310 K08UCB (2) .315 .290 5.000 1.400 .355 .250 1 H 08 UIRL..

SIR/L 0375 H11 (1) .380 .380 4.000 - .470 .290 0 S 11 IR/IL..

SIR/L 0375 K11 (1) .620 .380 5.000 1.000 .470 .260 0 S 11 IR/IL..

SIR/L 0375 K11B (1) .625 .380 5.000 .980 .470 .280 1 S 11 IR/IL..

SIR 0375 M11CB (2) .380 .380 6.000 - .500 .290 1 H 11 IR..

SIR/L 0500 L11 (1) .625 .500 5.500 1.250 .630 .320 0 S 11 IR/IL..

SIR 0500 P11CB (2) .500 .500 7.000 - .600 .330 1 H 11 IR..

SIR/L 0500 M16 (1) .625 .500 6.000 1.250 .640 .390 0 S 16 IR/IL..

SIR/L 0500 M16B (1) .625 .500 6.000 1.260 .640 .390 1 S 16 IR/IL..

SIR/L 0625 P16 (1) .750 .625 7.000 1.500 .750 .450 0 S 16 IR/IL..

SIR/L 0625 P16B (1) .750 .625 7.000 1.570 .750 .450 1 S 16 IR/IL..

SIR 0625 R16CB (2) .625 .625 8.000 - .750 .460 1 H 16 IR..

SIL 0750 P16 .750 .750 7.000 - 1.000 .510 0 S 16 IR/IL..

SIR 0750 P16 .750 .750 7.000 - .900 .510 0 S 16 IR/IL..

SIR 0750 P16B .750 .750 7.000 - .900 .510 1 S 16 IR..

SIR/L 1000 R16 1.000 1.000 8.000 - 1.200 .650 0 S 16 IR/IL..

SIR 1000 R16B 1.000 1.000 8.000 - 1.160 .650 1 S 16 IR..

SIR/L 1250 S16 1.250 1.250 10.000 - 1.420 .770 0 S 16 IR/IL..

SIR/L 1500 T16 1.500 1.500 12.000 - 1.650 .900 0 S 16 IR/IL..

SIR/L 0750 P22 .750 .750 7.000 - .950 .510 0 S 22 IR/IL..

SIR/L 1000 R22 1.000 1.000 8.000 - 1.200 .710 0 S 22 IR/IL..

SIR 1000 R22B 1.000 1.000 8.000 - 1.160 .710 1 S 22 IR..

SIR/L 1250 S22 1.250 1.250 10.000 - 1.500 .850 0 S 22 IR/IL..

SIR 1500 T22 1.500 1.500 12.000 - 1.750 .980 0 S 22 IR/IL..

SIR 1250 S22U 1.250 1.250 10.000 - 1.500 1.010 0 S 22 UIRL..

SIR 1500 T22U 1.500 1.500 12.000 - 1.850 1.120 0 S 22 UIRL..

SIR/L 1250 S27 1.250 1.250 10.000 - 1.560 .880 0 S 27 IR/IL..

SIR/L 1500 T27 1.500 1.500 12.000 - 1.800 1.000 0 S 27 IR/IL..

SIR 2000 U27 2.000 2.000 14.000 - 2.300 1.250 0 S 27 IR/IL..

SIL 2500 V27 2.500 2.500 12.600 - 2.700 1.500 0 S 27 IR/IL..

SIR/L 1250 S27U (3) 1.250 1.250 10.000 - 1.560 .980 0 S 27 UIRL..

SIL 1500 T27U (3) 1.500 1.500 12.000 - 1.850 1.130 0 S 27 UIRL..

SIR/L 2000 U27U (3) 2.000 2.000 14.000 - 2.300 1.370 0 S 27 UIRL..

• B-steel shank with coolant hole, C-carbide shank without coolant hole, CB-carbide shank with coolant hole

• All toolholders are made for 1.5 helix angle

• For GTGA inserts, use anvil AL 16-0

(1) Toolholder without anvil

(2) Carbide shank without anvil

(3) For ACME, STUB ACME, TRAPEZ (DIN 103) and ROUND (DIN 405) thread profiles check in user guide for anvil information

(4) 0 - Without coolant supply, 1 - With coolant supply

(5) H-carbide,S-steel

(6) Right-hand inserts (IR) for right-hand tools (SIR)

Inserts: GTGA • GTMA • IR-BUT • IR-EL • IR-MJ • IR/L-55° • IR/L-60° • IR/L-ABUT • IR/L-ACME • IR/L-API

• IR/L-API RD • IR/L-BSPT • IR/L-ISO • IR/L-NPT • IR/L-NPTF • IR/L-PG • IR/L-RND • IR/L-SAGE • IR/L-STACME • IR/L-TR • IR/L-UN • IR/L-UNJ • IR/L-W

243