Page 129 - THREADING CATALOG

P. 129

±0.025 17.7 Ref. (a)

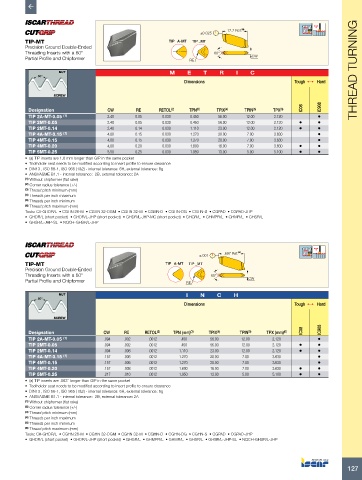

TIP-MT TIP _A-MT TIP _MT

Precision Ground Double-Ended

Threading Inserts with a 60° 60°

Partial Profile and Chipformer RE CW

NUT M E T R I C THREAD TURNING

60°

Dimensions Tough 1 Hard

SCREW

Designation CW RE RETOL (2) TPN (3) TPIX (4) TPIN (5) TPX (6) IC08 IC908

TIP 2A-MT-0.05 (1) 2.40 0.05 0.030 0.450 56.00 12.00 2.120 •

TIP 2MT-0.05 2.40 0.05 0.030 0.450 56.00 12.00 2.120 • •

TIP 2MT-0.14 2.40 0.14 0.030 1.110 23.00 12.00 2.120 • •

TIP 4A-MT-0.15 (1) 4.00 0.15 0.030 1.270 20.00 7.00 3.630 •

TIP 4MT-0.15 4.00 0.15 0.030 1.270 20.00 7.00 3.630 •

TIP 4MT-0.20 4.00 0.20 0.030 1.600 16.00 7.00 3.630 • •

TIP 5MT-0.25 5.50 0.25 0.030 1.950 13.00 5.00 5.100 • •

• (a) TIP inserts are 1.6 mm longer than GIP in the same pocket

• Toolholder seat needs to be modified according to insert profile to ensure clearance

• DIN13 , ISO 68-1, ISO 965 (1&2) - internal tolerance: 6H, external tolerance: 6g

• ANSI/ASME B1.1 - internal tolerance: 2B, external tolerance: 2A

(1) Without chipformer (flat rake)

(2) Corner radius tolerance (+/-)

(3) Thread pitch minimum (mm)

(4) Threads per inch maximum

(5) Threads per inch minimum

(6) Thread pitch maximum (mm)

Tools: C#-GHDR/L • CGHN 26-M • CGHN 32-DGM • CGHN 32-M • CGHN-D • CGHN-DG • CGHN-S • CGPAD • CGPAD-JHP

• GHDR/L (short pocket) • GHDR/L-JHP (short pocket) • GHDR/L-JHP-MC (short pocket) • GHGR/L • GHMPR/L • GHMR/L • GHSR/L

• GHSR/L-JHP-SL • NQCH-GHSR/L-JHP

±.001 .697 Ref. (a)

TIP-MT TIP _A-MT TIP _MT

Precision Ground Double-Ended

Threading Inserts with a 60° 60°

Partial Profile and Chipformer RE CW

NUT I N C H

60°

Dimensions Tough 1 Hard

SCREW

Designation CW RE RETOL (2) TPN (mm) (3) TPIX (4) TPIN (5) TPX (mm) (6) IC08 IC908

TIP 2A-MT-0.05 (1) .094 .002 .0012 .450 56.00 12.00 2.120 •

TIP 2MT-0.05 .094 .002 .0012 .450 56.00 12.00 2.120 • •

TIP 2MT-0.14 .094 .006 .0012 1.110 23.00 12.00 2.120 • •

TIP 4A-MT-0.15 (1) .157 .006 .0012 1.270 20.00 7.00 3.630 •

TIP 4MT-0.15 .157 .006 .0012 1.270 20.00 7.00 3.630 •

TIP 4MT-0.20 .157 .008 .0012 1.600 16.00 7.00 3.630 • •

TIP 5MT-0.25 .217 .010 .0012 1.950 13.00 5.00 5.100 • •

• (a) TIP inserts are .063" longer than GIP in the same pocket

• Toolholder seat needs to be modified according to insert profile to ensure clearance

• DIN13 , ISO 68-1, ISO 965 (1&2) - internal tolerance: 6H, external tolerance: 6g

• ANSI/ASME B1.1 - internal tolerance: 2B, external tolerance: 2A

(1) Without chipformer (flat rake)

(2) Corner radius tolerance (+/-)

(3) Thread pitch minimum (mm)

(4) Threads per inch maximum

(5) Threads per inch minimum

(6) Thread pitch maximum (mm)

Tools: C#-GHDR/L • CGHN 26-M • CGHN 32-DGM • CGHN 32-M • CGHN-D • CGHN-DG • CGHN-S • CGPAD • CGPAD-JHP

• GHDR/L (short pocket) • GHDR/L-JHP (short pocket) • GHGR/L • GHMPR/L • GHMR/L • GHSR/L • GHSR/L-JHP-SL • NQCH-GHSR/L-JHP

127