Page 31 - machining_titanium_05_2019

P. 31

Avoid misunderstanding: titanium beta (β)

An incorrect interpretation of shop talk may cause serious misunderstandings and even

wrong decisions. In many cases, “titanium-beta”, so freely used in manufacturing, does not

mean β-alloys but β-(beta-) annealed α-β-alloys, in particular for the “universal” Ti-6Al-4V. MILLING TITANIUM

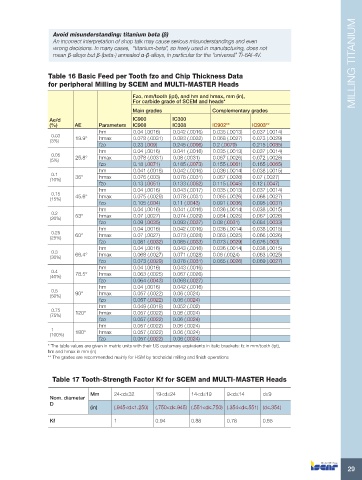

Table 16 Basic Feed per Tooth fzo and Chip Thickness Data

for peripheral Milling by SCEM and MULTI-MASTER Heads

Fzo, mm/tooth (ipt), and hm and hmax, mm (in),

For carbide grade of SCEM and heads*

Main grades Complementary grades

Ae/d IC900 IC300

(%) AE Parameters IC908 IC308 IC902** IC903**

hm 0.04 (.0016) 0.042 (.0016) 0.035 (.0013) 0.037 (.0014)

0.03 19.9° hmax 0.078 (.0031) 0.083 (.0032) 0.068 (.0027) 0.073 (.0029)

(3%)

fzo 0.23 (.009) 0.245 (.0096) 0.2 (.0079) 0.215 (.0085)

hm 0.04 (.0016) 0.041 (.0016) 0.035 (.0013) 0.037 (.0014)

0.05 25.8° hmax 0.078 (.0031) 0.08 (.0031) 0.067 (.0026) 0.072 (.0028)

(5%)

fzo 0.18 (.0071) 0.185 (.0073) 0.155 (.0061) 0.165 (.0065)

hm 0.041 (.0016) 0.042 (.0016) 0.036 (.0014) 0.038 (.0015)

0.1 36° hmax 0.076 (.003) 0.078 (.0031) 0.067 (.0026) 0.07 (.0027)

(10%)

fzo 0.13 (.0051) 0.133 (.0052) 0.115 (.0045) 0.12 (.0047)

hm 0.04 (.0016) 0.043 (.0017) 0.035 (.0013) 0.037 (.0014)

0.15 45.6° hmax 0.075 (.0029) 0.078 (.0031) 0.065 (.0026) 0.068 (.0027)

(15%)

fzo 0.105 (.004) 0.11 (.0043) 0.091 (.0036) 0.095 (.0037)

hm 0.04 (.0016) 0.041 (.0016) 0.036 (.0014) 0.038 (.0015)

0.2 53° hmax 0.07 (.0027) 0.074 (.0029) 0.064 (.0025) 0.067 (.0026)

(20%)

fzo 0.09 (.0035) 0.093 (.0037) 0.08 (.0031) 0.084 (.0033)

hm 0.04 (.0016) 0.042 (.0016) 0.036 (.0014) 0.038 (.0015)

0.25 60° hmax 0.07 (.0027) 0.073 (.0028) 0.063 (.0025) 0.066 (.0026)

(25%)

fzo 0.081 (.0032) 0.085 (.0033) 0.073 (.0029) 0.076 (.003)

hm 0.04 (.0016) 0.043 (.0016) 0.036 (.0014) 0.038 (.0015)

0.3 66.4° hmax 0.068 (.0027) 0.071 (.0028) 0.06 (.0024) 0.063 (.0025)

(30%)

fzo 0.073 (.0029) 0.078 (.0031) 0.065 (.0026) 0.069 (.0027)

hm 0.04 (.0016) 0.043 (.0016)

0.4 78.5° hmax 0.063 (.0025) 0.067 (.0026)

(40%)

fzo 0.064 (.0043) 0.068 (.0027)

hm 0.04 (.0016) 0.042 (.0016)

0.5 90° hmax 0.057 (.0022) 0.06 (.0024)

(50%)

fzo 0.057 (.0022) 0.06 (.0024)

hm 0.049 (.0019) 0.052 (.002)

0.75 120° hmax 0.057 (.0022) 0.06 (.0024)

(75%)

fzo 0.057 (.0022) 0.06 (.0024)

hm 0.057 (.0022) 0.06 (.0024)

1 180° hmax 0.057 (.0022) 0.06 (.0024)

(100%)

fzo 0.057 (.0022) 0.06 (.0024)

* The table values are given in metric units with their US customary equivalents in italic brackets: fz in mm/tooth (ipt),

hm and hmax in mm (in)

** The grades are recommended mainly for HSM by trochoidal milling and finish operations

Table 17 Tooth-Strength Factor Kf for SCEM and MULTI-MASTER Heads

Mm 24<d≤32 19<d≤24 14<d≤19 9<d≤14 d≤9

Nom. diameter

D

(in) (.945<d≤1.250) (.750<d≤.945) (.551<d≤.750) (.354<d≤.551) (d≤.354)

Kf 1 0.94 0.88 0.78 0.65

29