Page 11 - machining_titanium_05_2019

P. 11

MILLING TITANIUM

Cemented Carbide Grades for Milling Titanium

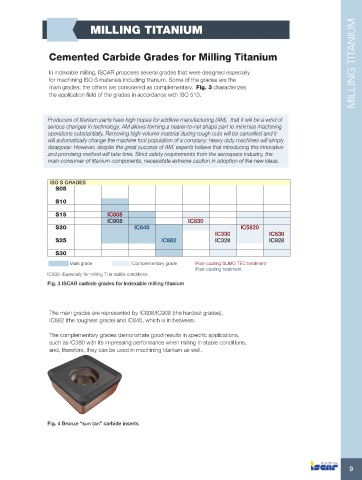

In indexable milling, ISCAR proposes several grades that were designed especially MILLING TITANIUM

for machining ISO S materials including titanium. Some of the grades are the

main grades; the others are considered as complementary. Fig. 3 characterizes

the application field of the grades in accordance with ISO 513.

Producers of titanium parts have high hopes for additive manufacturing (AM), that it will be a wind of

serious changes in technology. AM allows forming a nearer-to-net shape part to minimize machining

operations substantially. Removing high-volume material during rough cuts will be cancelled and it

will automatically change the machine tool population of a company: heavy duty machines will simply

disappear. However, despite the great success of AM, experts believe that introducing this innovative

and promising method will take time. Strict safety requirements from the aerospace industry, the

main consumer of titanium components, necessitate extreme caution in adoption of the new ideas.

ISO S GRADES

S05

S10

S15 IC808

IC908 IC830

S20 IC840 IC5820

IC330 IC830

S25 IC882 IC328 IC928

S30

Main grade Complementary grade Post-coating SUMO TEC treatment

Post-coating treatment

IC380- Especially for milling Ti in stable conditions

Fig. 3 ISCAR carbide grades for indexable milling titanium

The main grades are represented by IC808/IC908 (the hardest grades),

IC882 (the toughest grade) and IC840, which is in between.

The complementary grades demonstrate good results in specific applications,

such as IC380 with its impressing performance when milling in stable conditions,

and, therefore, they can be used in machining titanium as well.

Fig. 4 Bronze “sun tan” carbide inserts

9