Page 81 - ISCAR FACE GROOVING LINES

P. 81

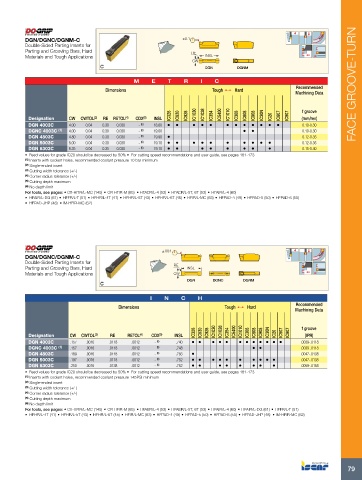

DGN/DGNC/DGNM-C IC328±0.1

Double-Sided Parting Inserts for IC830

Parting and Grooving Bars, Hard IC928RE INSL

Materials and Tough Applications IC1030CW

IC1028

IC354DGNDGNM

IC5400

METRIC IC1010

IC308

Dimensions IC808Tough 1 Hard Recommended

IC908 Machining Data

IC30N

IC20 f groove

IC807

Designation CW CWTOL(3) RE RETOL(4) CDX(5) INSL IC907•••(mm/rev)

•••

DGN 4003C 4.00 0.04 0.30 0.030 - (6) 18.80 • • FACE GROOVE-TURN 0.10-0.30

DGNC 4003C (1) 4.00 0.04 0.30 0.030 - (6) •• ••••••• 0.10-0.30

DGN 4803C 4.80 0.04 0.30 0.030 - (6) 19.00 •• 0.12-0.35

DGN 5003C 5.00 0.04 0.30 0.030 - (6) 0.12-0.35

DGN 6303C 6.35 0.04 0.35 0.030 - (6) 19.90 • • •••• 0.15-0.40

19.10 • • • •• •

19.10 • •

• Feed values for grade IC20 should be decreased by 50% • For cutting speed recommendations and user guide, see pages 161-173

(1) Inserts with coolant holes, recommended coolant pressure 10 bar minimum

(2) Single-ended insert

(3) Cutting width tolerance (+/-)

(4) Corner radius tolerance (+/-)

(5) Cutting depth maximum

(6) No depth limit

For tools, see pages: • C#-HFIR/L-MC (145) • CR HFIR-M (65) • HFAER/L-4 (53) • HFAER/L-5T, 6T (53) • HFAIR/L-4 (60)

• HFAIR/L-DG (61) • HFFR/L-T (51) • HFHR/L-4T (41) • HFHR/L-5T (43) • HFHR/L-6T (45) • HFIR/L-MC (63) • HFPAD-4 (49) • HFPAD-5 (50) • HFPAD-6 (50)

• HFPAD-JHP (48) • IM-HFIR-MC (62)

DGN/DGNC/DGNM-C ±.004

Double-Sided Parting Inserts for

Parting and Grooving Bars, Hard RE INSL

Materials and Tough Applications CW

DGN DGNC DGNM

INCH Tough 1 Hard Recommended

Dimensions Machining Data

IC328 f groove

IC830

CW CWTOL(3) RE RETOL(4) CDX(5) IC928 (IPR)

IC1030

.157 .0016 .0118 .0012 - (6) IC1028 .0039-.0118

.157 .0016 .0118 .0012 - (6) IC354 .0039-.0118

.189 .0016 .0118 .0012 - (6) IC5400 .0047-.0138

.197 .0016 .0118 .0012 - (6) IC1010 .0047-.0138

.250 .0016 .0138 .0012 - (6) IC308 .0059-.0158

IC808

IC908

IC30N

IC20

IC807

IC907

Designation INSL

••• •••••••

DGN 4003C .740 • • ••• ••

DGNC 4003C (1)

DGN 4803C .748 •• • ••••

DGN 5003C • •• •

DGN 6303C .783 •

.752 • •

.752 • •

• Feed values for grade IC20 should be decreased by 50% • For cutting speed recommendations and user guide, see pages 161-173

(1) Inserts with coolant holes, recommended coolant pressure 145PSI minimum

(2) Single-ended insert

(3) Cutting width tolerance (+/-)

(4) Corner radius tolerance (+/-)

(5) Cutting depth maximum

(6) No depth limit

For tools, see pages: • C#-HFIR/L-MC (145) • CR HFIR-M (65) • HFAER/L-4 (53) • HFAER/L-5T, 6T (53) • HFAIR/L-4 (60) • HFAIR/L-DG (61) • HFFR/L-T (51)

• HFHR/L-4T (41) • HFHR/L-5T (43) • HFHR/L-6T (45) • HFIR/L-MC (63) • HFPAD-4 (49) • HFPAD-5 (50) • HFPAD-6 (50) • HFPAD-JHP (48) • IM-HFIR-MC (62)

79