Page 139 - ISCAR FACE GROOVING LINES

P. 139

CAMFIX FACE GROOVE-TURN

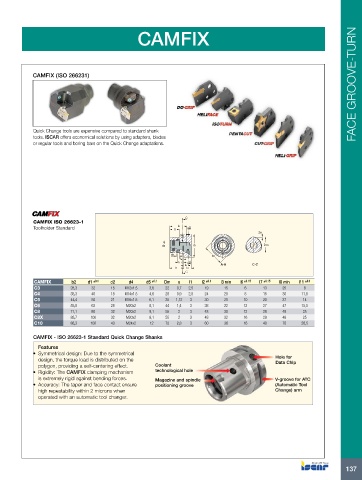

CAMFIX (ISO 266231)

Quick Change tools are expensive compared to standard shank

tools. ISCAR offers economical solutions by using adapters, blades

or regular tools and boring bars on the Quick Change adaptations.

CAMFIX ISO 26623-1 C

Toolholder Standard

l8 A

l7

2e

d4

d2 d1 Dm

C-C

d5 A b2

l1 l6 A-A

l11

l3

l2 C

CAMFIX b2 d1 ±0.1 d2 d4 d5 ±0.1 Dm e l1 l2 ±0.1 l3 min l6 ±0.15 l7 ±0.15 l8 min l11 ±0.1

28,3 32

C3 35,3 40 15 M12x1.5 3,6 22 0,7 2,5 19 15 6 13 25 8

C4 44,4 50

C5 55,8 63 18 M14x1.5 4,6 28 0,9 2,5 24 20 8 15 30 11,5

C6 71,1 80

C8 88,7 100 21 M16x1.5 6,1 35 1,12 3 30 20 10 20 37 14

C8X 88,3 100

C10 28 M20x2 8,1 44 1,4 3 38 22 12 27 47 15,5

32 M20x2 9,1 55 2 3 48 30 12 28 48 25

32 M20x2 9,1 55 2 3 48 32 16 28 48 25

43 M24x2 12 72 2,8 3 60 36 16 40 70 26,5

CAMFIX - ISO 26623-1 Standard Quick Change Shanks

Features Coolant Hole for

• Symmetrical design: Due to the symmetrical technological hole Data Chip

Magazine and spindle V-groove for ATC

design, the torque load is distributed on the positioning groove (Automatic Tool

polygon, providing a self-centering effect. Change) arm

• Rigidity: The CAMFIX clamping mechanism

is extremely rigid against bending forces.

• Accuracy: The taper and face contact ensure

high repeatability within 2 microns when

operated with an automatic tool changer.

137