Page 99 - THREADING CATALOG

P. 99

USER GUIDE

THREAD TURNING

Tool Configuration

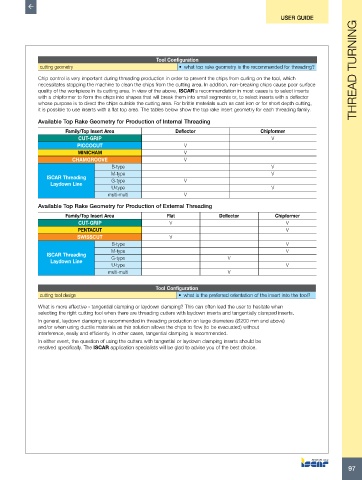

cutting geometry • what top rake geometry is the recommended for threading?

Chip control is very important during threading production in order to prevent the chips from curling on the tool, which

necessitates stopping the machine to clean the chips from the cutting area. In addition, non-breaking chips cause poor surface

quality of the workpiece in its cutting area. In view of the above, ISCAR’s recommendation in most cases is to select inserts

with a chipformer to form the chips into shapes that will break them into small segments or, to select inserts with a deflector

whose purpose is to direct the chips outside the cutting area. For brittle materials such as cast iron or for short depth cutting,

it is possible to use inserts with a flat top area. The tables below show the top rake insert geometry for each threading family.

Available Top Rake Geometry for Production of Internal Threading

Family/Top Insert Area Deflector Chipformer

CUT-GRIP V

PICCOCUT V

MINICHAM V

CHAMGROOVE V

B-type V

M-type V

ISCAR Threading

Laydown Line G-type V

U-type V

multi-multi V

Available Top Rake Geometry for Production of External Threading

Family/Top Insert Area Flat Deflector Chipformer

CUT-GRIP V V

PENTACUT V

SWISSCUT V

B-type V

M-type V

ISCAR Threading

Laydown Line G-type V

U-type V

multi-multi V

Tool Configuration

cutting tool design • what is the preferred orientation of the insert into the tool?

What is more effective - tangential clamping or laydown clamping? This can often lead the user to hesitate when

selecting the right cutting tool when there are threading cutters with laydown inserts and tangentially clamped inserts.

In general, laydown clamping is recommended in threading production on large diameters (Ø200 mm and above)

and/or when using ductile materials as this solution allows the chips to flow (to be evacuated) without

interference, easily and efficiently. In other cases, tangential clamping is recommended.

In either event, the question of using the cutters with tangential or laydown clamping inserts should be

resolved specifically. The ISCAR application specialists will be glad to advise you of the best choice.

97