Page 102 - THREADING CATALOG

P. 102

USER GUIDE

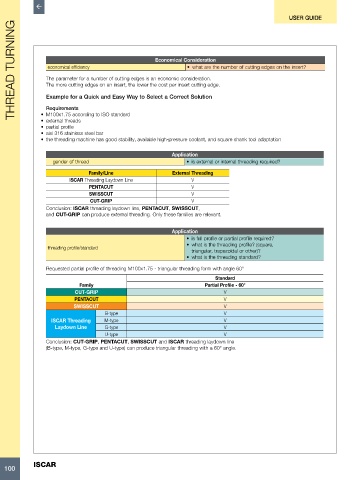

THREAD TURNING The parameter for a number of cutting edges is an economic consideration.

Economical Consideration

• what are the number of cutting edges on the insert?

economical efficiency

The more cutting edges on an insert, the lower the cost per insert cutting edge.

Example for a Quick and Easy Way to Select a Correct Solution

Requirements

• M100x1.75 according to ISO standard

• external threads

• partial profile

• aisi 316 stainless steel bar

• the threading machine has good stability, available high-pressure coolant, and square shank tool adaptation

Application

gender of thread • is external or internal threading required?

Family/Line External Threading

ISCAR Threading Laydown Line V

PENTACUT V

SWISSCUT V

CUT-GRIP V

Conclusion: ISCAR threading laydown line, PENTACUT, SWISSCUT,

and CUT-GRIP can produce external threading. Only these families are relevant.

Application

• is full profile or partial profile required?

• what is the threading profile? (square,

threading profile/standard

triangular, trapezoidal or other)?

• what is the threading standard?

Requested partial profile of threading M100x1.75 - triangular threading form with angle 60°

Standard

Family Partial Profile - 60°

CUT-GRIP V

PENTACUT V

SWISSCUT V

B-type V

ISCAR Threading M-type V

Laydown Line G-type V

U-type V

Conclusion: CUT-GRIP, PENTACUT, SWISSCUT and ISCAR threading laydown line

(B-type, M-type, G-type and U-type) can produce triangular threading with a 60° angle.

ISCAR

100