Page 80 - THREADING CATALOG

P. 80

USER GUIDE

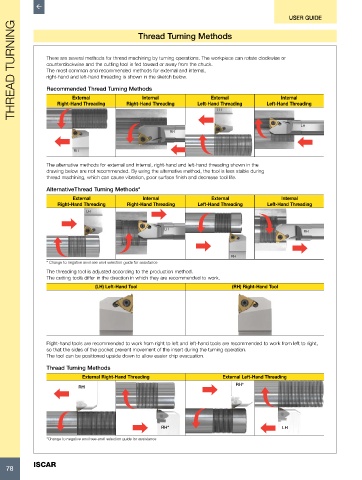

THREAD TURNING There are several methods for thread machining by turning operations. The workpiece can rotate clockwise or

Thread Turning Methods

counterclockwise and the cutting tool is fed toward or away from the chuck.

The most common and recommended methods for external and internal,

right-hand and left-hand threading is shown in the sketch below.

Recommended Thread Turning Methods

Internal

External

External

Internal

Left-Hand Threading

Left-Hand Threading

Right-Hand Threading

Right-Hand Threading

LH

LH

RH

RH

The alternative methods for external and internal, right-hand and left-hand threading shown in the

drawing below are not recommended. By using the alternative method, the tool is less stable during

thread machining, which can cause vibration, poor surface finish and decrease tool life.

AlternativeThread Turning Methods*

External Internal External Internal

Right-Hand Threading Right-Hand Threading Left-Hand Threading Left-Hand Threading

LH

LH

RH

RH

* Change to negative anvil see anvil selection guide for assistance

The threading tool is adjusted according to the production method.

The cutting tools differ in the direction in which they are recommended to work.

(LH) Left-Hand Tool (RH) Right-Hand Tool

Right-hand tools are recommended to work from right to left and left-hand tools are recommended to work from left to right,

so that the sides of the pocket prevent movement of the insert during the turning operation.

The tool can be positioned upside down to allow easier chip evacuation.

Thread Turning Methods

External Right-Hand Threading External Left-Hand Threading

RH*

RH

RH* LH

*Change to negative anvil see anvil selection guide for assistance

ISCAR

78