Page 44 - THREADING CATALOG

P. 44

USER GUIDE

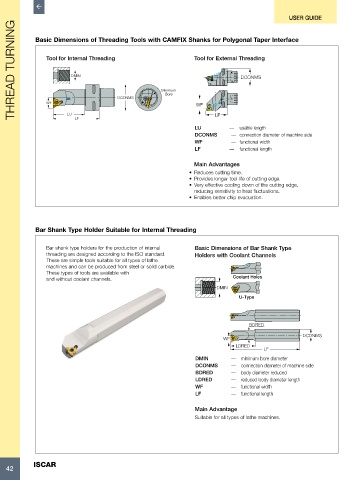

THREAD TURNING Tool for Internal Threading DCONMS Minimum Tool for External Threading

Basic Dimensions of Threading Tools with CAMFIX Shanks for Polygonal Taper Interface

DMIN

DCONMS

Bore

WF

WF

LU

LF

LU LF — usable length

DCONMS — connection diameter of machine side

WF — functional width

LF — functional length

Main Advantages

• Reduces cutting time.

• Provides longer tool life of cutting edge.

• Very effective cooling down of the cutting edge,

reducing sensitivity to heat fluctuations.

• Enables better chip evacuation.

Bar Shank Type Holder Suitable for Internal Threading

Bar shank type holders for the production of internal Basic Dimensions of Bar Shank Type

threading are designed according to the ISO standard. Holders with Coolant Channels

These are simple tools suitable for all types of lathe

machines and can be produced from steel or solid carbide.

These types of tools are available with

and without coolant channels. Coolant Holes

DMIN

U-Type

BDRED

DCONMS

WF

LDRED

LF

DMIN — minimum bore diameter

DCONMS — connection diameter of machine side

BDRED — body diameter reduced

LDRED — reduced body diameter length

WF — functional width

LF — functional length

Main Advantage

Suitable for all types of lathe machines.

ISCAR

42