Page 43 - machining_titanium_05_2019

P. 43

Carbide Grades

HFM demands tough carbide grades. In indexable milling, IC882 is the first choice and

IC330, IC328, and IC840 are reasonable options. Solid carbide FF endmills are produced

from grades IC903 and IC902, and FF MULTI-MASTER heads – from IC903 and IC908. MILLING TITANIUM

Initial Cutting Data

Initial cutting speed Vc can be found using equation (1), where the basic cutting speed and

factors, which the equation uses, are in Tables 7-10. Basic cutting speed Vo should be

chosen from data for medium (M) type of machining. As in the previous cases, stability factor

Ks is defined as 1 for normal stability and 0.-0.8 for unstable machining conditions.

Note. In milling cavities and pockets, in many cases an FF tool starts from cutting solid material by

ramping down (with AE=180°) and then continues to machine the shoulder. For a rough calculation

of Vc it is enough to simplify equation (1) by setting engagement factor Ke as 1.

Starting feed per tooth fz for indexable FF tools is specified by equation (5):

fz=fzo×Ks

Table 26 provides basic feeds depending on carbide grades of inserts,

and Table 27 – for SCEM and MULTI-MASTER heads.

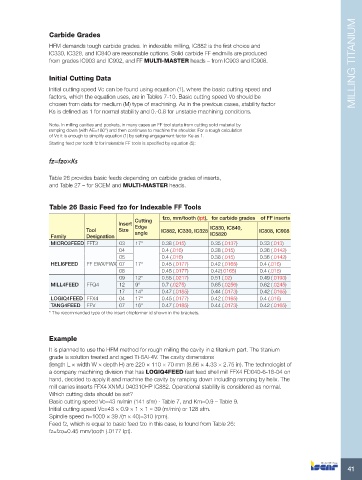

Table 26 Basic Feed fzo for Indexable FF Tools

fzo, mm/tooth (ipt), for carbide grades of FF inserts

Cutting

Insert Edge

Tool Size angle IC882, IC330, IC328 IC830, IC840, IC808, IC908

Family Designation IC5820

MICRO3FEED FFT3 03 17° 0.38 (.015) 0.35 (.0137) 0.33 (.013)

04 0.4 (.016) 0.38 (.015) 0.36 (.0142)

05 0.4 (.016) 0.38 (.015) 0.36 (.0142)

HELI6FEED FF EWX/FWX 07 17° 0.45 (.0177) 0.42 (.0165) 0.4 (.016)

08 0.45 (.0177) 0.42(.0165) 0.4 (.016)

09 12° 0.55 (.0217) 0.51 (.02) 0.49 (.0193)

MILL4FEED FFQ4 12 9° 0.7 (.0275) 0.65 (.0256) 0.62 (.0245)

17 14° 0.47 (.0185) 0.44 (.0173) 0.42 (.0165)

LOGIQ4FEED FFX4 04 17° 0.45 (.0177) 0.42 (.0165) 0.4 (.016)

TANG4FEED FFV 07 16° 0.47 (.0185) 0.44 (.0173) 0.42 (.0165)

* The recommended type of the insert chipformer id shown in the brackets.

Example

It is planned to use the HFM method for rough milling the cavity in a titanium part. The titanium

grade is solution treated and aged Ti-6Al-4V. The cavity dimensions

(length L × width W × depth H) are 220 × 110 × 70 mm (8.66 × 4.33 × 2.75 in). The technologist of

a company machining division that has LOGIQ4FEED fast feed shell mill FFX4 FD040-6-16-04 on

hand, decided to apply it and machine the cavity by ramping down including ramping by helix. The

mill carries inserts FFX4 XNMU 040310HP IC882. Operational stability is considered as normal.

Which cutting data should be set?

Basic cutting speed Vo=43 m/min (141 sfm) - Table 7, and Km=0.9 – Table 9.

Initial cutting speed Vc=43 × 0.9 × 1 × 1 ≈ 39 (m/min) or 128 sfm.

Spindle speed n=1000 × 39 /(π × 40)=310 (rpm).

Feed fz, which is equal to basic feed fzo in this case, is found from Table 26:

fz=fzo=0.45 mm/tooth (.0177 ipt).

41