Page 63 - ISCAR FACE GROOVING LINES

P. 63

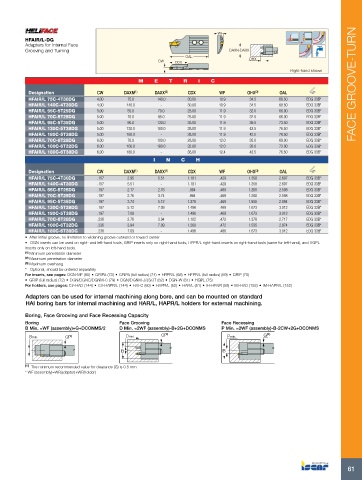

HFAIR/L-DG WF FACE GROOVE-TURN

Adapters for Internal Face

Grooving and Turning DAXN-DAXX

OHX

OAL

CW CDX

Right-hand shown

METRIC

Designation CW DAXN(1) DAXX(2) CDX WF OHX(3) OAL EDG 33B*

4.00 75.0 140.0 30.00 10.9 34.5 68.50 EDG 33B*

HFAIR/L 75C-4T30DG 4.00 140.0 - 30.00 10.9 34.5 68.50 EDG 33B*

HFAIR/L 140C-4T30DG 5.00 55.0 70.0 25.00 11.9 32.0 66.00 EDG 33B*

HFAIR/L 55C-5T25DG 5.00 70.0 95.0 25.00 11.9 32.0 66.00 EDG 33B*

HFAIR/L 70C-5T25DG 5.00 95.0 130.0 35.00 11.9 39.5 73.50 EDG 33B*

HFAIR/L 95C-5T35DG 5.00 130.0 180.0 38.00 11.9 42.5 76.50 EDG 33B*

HFAIR/L 130C-5T38DG 5.00 180.0 - 38.00 11.9 42.5 76.50 EDG 33B*

HFAIR/L 180C-5T38DG 6.00 70.0 100.0 28.00 12.0 35.0 69.00 EDG 33B*

HFAIR/L 70C-6T28DG 6.00 100.0 180.0 32.00 12.0 39.0 73.00 EDG 33B*

HFAIR/L 100C-6T32DG 6.00 180.0 - 38.00 12.4 42.5 76.50

HFAIR/L 180C-6T38DG

IN CH

Designation CW DAXN(1) DAXX(2) CDX WF OHX(3) OAL

HFAIR/L 75C-4T30DG .157 2.95 5.51 1.181 .429 1.358 2.697 EDG 33B*

HFAIR/L 140C-4T30DG .157 5.51 - 1.181 .429 1.358 2.697 EDG 33B*

HFAIR/L 55C-5T25DG .197 2.17 2.76 .984 .469 1.260 2.598 EDG 33B*

HFAIR/L 70C-5T25DG .197 2.76 3.74 .984 .469 1.260 2.598 EDG 33B*

HFAIR/L 95C-5T35DG .197 3.74 5.12 1.378 .469 1.555 2.894 EDG 33B*

HFAIR/L 130C-5T38DG .197 5.12 7.09 1.496 .469 1.673 3.012 EDG 33B*

HFAIR/L 180C-5T38DG .197 7.09 - 1.496 .469 1.673 3.012 EDG 33B*

HFAIR/L 70C-6T28DG .236 2.76 3.94 1.102 .472 1.378 2.717 EDG 33B*

HFAIR/L 100C-6T32DG .236 3.94 7.09 1.260 .472 1.535 2.874 EDG 33B*

HFAIR/L 180C-6T38DG .236 7.09 - 1.496 .488 1.673 3.012 EDG 33B*

• After initial groove, no limitation to widening groove outward or toward center

• DGN inserts can be used on right- and left-hand tools, GRIP inserts only on right-hand tools, HFPR/L right-hand inserts on right-hand tools (same for left-hand), and HGPL

inserts only on left-hand tools.

(1) Minimum penetration diameter

(2) Maximum penetration diameter

(3) Maximum overhang

* Optional, should be ordered separately

For inserts, see pages: DGN-MF (80) • GRIPA (73) • GRIPA (full radius) (74) • HFPR/L (68) • HFPR/L (full radius) (69) • GRIP (70)

• GRIP (full radius) (72) • DGN/DGNC/DGNM-C (79) • DGN/DGNM-J/JS/JT (82) • DGN-W (81) • HGPL (75)

For holders, see pages: C#-HAD (144) • C#-HAPR/L (144) • HAI-C (60) • HAPR/L (52) • HAR/L (51) • IH-HFAIR (58) • IM-HAD (152) • IM-HAPR/L (152)

Adapters can be used for internal machining along bore, and can be mounted on standard

HAI boring bars for internal machining and HAR/L, HAPR/L holders for external machining.

Boring, Face Grooving and Face Recessing Capacity

Boring Face Grooving Face Recessing

B Min. =WF (assembly)+G+DCONMS/2 D Min. =2WF (assembly)-B+2G+DCONMS P Min. =2WF (assembly)-B-2CW+2G+DCONMS

Bmin. G(1) Dmin. G(1) Pmin. G(1)

BB

(1) The minimum recommended value for clearance (G) is 0.5 mm

* WF (assembly)=WF(adapter)+WF(holder)

61