Page 16 - parting_4_productivity_3375101

P. 16

±0.1

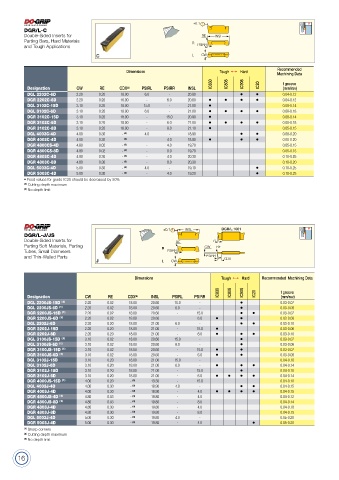

DGR/L-C

Double-Sided Inserts for RE INSL

Parting Bars, Hard Materials R

and Tough Applications PSIRR

L CW

Recommended

Dimensions Tough 1 Hard

Machining Data

IC830 IC808 IC908 IC20 f groove

Designation CW RE CDX (2) PSIRL PSIRR INSL (mm/rev)

DGL 2202C-6D 2.20 0.20 18.00 6.0 - 20.80 • • 0.04-0.12

DGR 2202C-6D 2.20 0.20 18.00 - 6.0 20.80 • • • • 0.04-0.12

DGL 3102C-15D 3.10 0.20 18.00 15.0 - 21.00 • 0.08-0.14

DGL 3102C-6D 3.10 0.20 18.00 6.0 - 21.00 • • • • 0.08-0.18

DGR 3102C-15D 3.10 0.20 18.00 - 15.0 20.90 • 0.08-0.14

DGR 3102C-6D 3.10 0.20 18.00 - 6.0 21.00 • • • • 0.08-0.18

DGR 3102C-8D 3.10 0.20 18.00 - 8.0 21.10 • 0.05-0.15

DGL 4003C-4D 4.00 0.30 - (3) 4.0 - 18.90 • • 0.08-0.20

DGR 4003C-4D 4.00 0.30 - - 4.0 18.80 • • • 0.08-0.20

(3)

DGR 4800CS-4D 4.80 0.02 - - 4.0 19.70 0.05-0.15

(3)

DGR 4800CS-8D 4.80 0.02 - - 8.0 19.70 0.05-0.15

(3)

DGR 4803C-4D 4.80 0.30 - - 4.0 20.30 0.10-0.25

(3)

DGR 4803C-8D 4.80 0.30 - - 8.0 20.30 0.10-0.20

(3)

DGL 5003C-4D 5.00 0.30 - 4.0 - 19.10 • 0.10-0.25

(3)

DGR 5003C-4D 5.00 0.30 - - 4.0 19.20 • 0.10-0.25

(3)

• Feed values for grade IC20 should be decreased by 50%

(2) Cutting depth maximum

(3) No depth limit

±0.1 INSL DGR/L 1001

DGR/L-J/JS

Double-Sided Inserts for RE 7°

Parting Soft Materials, Parting R CW RE

Tubes, Small Diameters PSIRR

and Thin-Walled Parts PSIRR CDX

L CW

Dimensions Tough 1 Hard Recommended Machining Data

IC830 IC808 IC908 IC20 f groove

Designation CW RE CDX (2) INSL PSIRL PSIRR (mm/rev)

DGL 2200JS-15D (1) 2.20 0.02 18.00 20.60 15.0 - • 0.03-0.07

DGL 2200JS-6D (1) 2.20 0.02 18.00 20.60 6.0 - • 0.03-0.08

DGR 2200JS-15D (1) 2.20 0.02 18.00 20.60 - 15.0 • • 0.03-0.07

DGR 2200JS-6D (1) 2.20 0.02 18.00 20.60 - 6.0 • • 0.03-0.08

DGL 2202J-6D 2.20 0.20 18.00 21.00 6.0 - • • 0.03-0.10

DGR 2202J-15D 2.20 0.20 18.00 21.00 - 15.0 • 0.03-0.08

DGR 2202J-6D 2.20 0.20 18.00 21.00 - 6.0 • • • 0.03-0.10

DGL 3100JS-15D (1) 3.10 0.02 18.00 20.60 15.0 - • 0.03-0.07

DGL 3100JS-6D (1) 3.10 0.02 18.00 20.60 6.0 - • 0.03-0.08

DGR 3100JS-15D (1) 3.10 0.02 18.00 20.60 - 15.0 • • 0.03-0.07

DGR 3100JS-6D (1) 3.10 0.02 18.00 20.60 - 6.0 • • 0.03-0.08

DGL 3102J-15D 3.10 0.20 18.00 21.00 15.0 - 0.04-0.10

DGL 3102J-6D 3.10 0.20 18.00 21.00 6.0 - • • • 0.04-0.14

DGR 3102J-15D 3.10 0.20 18.00 21.00 - 15.0 • 0.04-0.10

DGR 3102J-6D 3.10 0.20 18.00 21.00 - 6.0 • • • • 0.04-0.14

DGR 4000JS-15D (1) 4.00 0.20 - (3) 19.30 - 15.0 0.04-0.10

DGL 4003J-4D 4.00 0.30 - 18.90 4.0 - • • 0.04-0.15

(3)

DGR 4003J-4D 4.00 0.30 - 18.90 - 4.0 • • • • 0.04-0.15

(3)

DGR 4800JS-4D (1) 4.80 0.03 - 19.80 - 4.0 0.04-0.12

(3)

DGR 4800JS-8D (1) 4.80 0.03 - 19.80 - 8.0 0.04-0.14

(3)

DGR 4803J-4D 4.80 0.30 - 19.80 - 4.0 0.04-0.18

(3)

DGR 4803J-8D 4.80 0.30 - 19.80 - 8.0 0.04-0.15

(3)

DGL 5003J-4D 5.00 0.30 - 19.80 4.0 - 0.05-0.20

(3)

DGR 5003J-4D 5.00 0.30 - 19.80 - 4.0 • 0.05-0.20

(3)

(1) Sharp corners

(2) Cutting depth maximum

(3) No depth limit

16