Page 15 - parting_4_productivity_3375101

P. 15

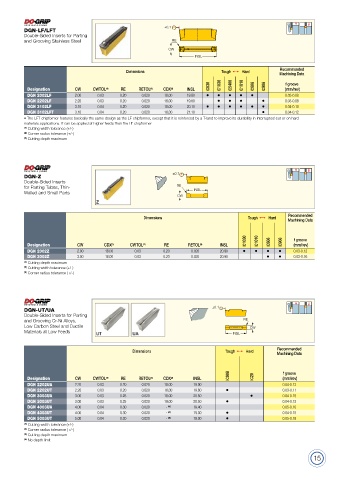

DGN-LF/LFT ±0.1

Double-Sided Inserts for Parting

and Grooving Stainless Steel RE

CW

INSL

Recommended

Dimensions Tough 1 Hard

Machining Data

f groove

Designation CW CWTOL (1) RE RETOL (2) CDX (3) INSL IC830 IC1030 IC5400 IC1010 IC808 IC908 (mm/rev)

DGN 2002LF 2.00 0.03 0.20 0.020 18.00 19.80 • • • • • 0.03-0.08

DGN 2202LF 2.20 0.03 0.20 0.020 18.00 19.80 • • • • 0.03-0.08

DGN 3102LF 3.10 0.04 0.20 0.020 18.00 20.10 • • • • • • 0.04-0.10

DGN 3102LFT 3.10 0.04 0.20 0.020 18.00 21.10 • 0.04-0.12

• The LFT chipformer features basically the same design as the LF chipformer, except that it is reinforced by a T-land to improve its durability in interrupted-cut or on hard

materials applications. It can be applied at higher feeds than the LF chipformer

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

DGN-Z ±0.1

Double-Sided Inserts

for Parting Tubes, Thin- RE INSL

Walled and Small Parts

CW

Recommended

Dimensions Tough 1 Hard Machining Data

IC1030 IC1010 IC808 IC908 f groove

Designation CW CDX (1) CWTOL (2) RE RETOL (3) INSL (mm/rev)

DGN 2002Z 2.00 18.00 0.03 0.20 0.020 20.90 • • • • 0.03-0.12

DGN 3002Z 3.00 18.00 0.03 0.20 0.020 20.90 • • 0.03-0.16

(1) Cutting depth maximum

(2) Cutting width tolerance (+/-)

(3) Corner radius tolerance (+/-)

DGN-UT/UA ±0.1

Double-Sided Inserts for Parting

and Grooving Cr-Ni Alloys, RE

Low Carbon Steel and Ductile CW

Materials at Low Feeds INSL

Recommended

Dimensions Tough 1 Hard Machining Data

IC908 IC20 f groove

Designation CW CWTOL (1) RE RETOL (2) CDX (3) INSL (mm/rev)

DGN 2202UA 2.20 0.03 0.20 0.020 18.00 19.90 0.04-0.13

DGN 2202UT 2.20 0.03 0.20 0.020 18.00 19.60 • 0.03-0.11

DGN 3003UA 3.00 0.03 0.25 0.020 18.00 20.50 • 0.04-0.15

DGN 3003UT 3.00 0.03 0.25 0.020 18.00 20.50 • 0.04-0.13

DGN 4003UA 4.00 0.04 0.30 0.020 - (4) 19.40 0.05-0.16

DGN 4003UT 4.00 0.04 0.30 0.020 - 19.30 • 0.04-0.15

(4)

DGN 5003UT 5.00 0.04 0.30 0.020 - 19.00 • 0.05-0.18

(4)

Cutting width tolerance (+/-)

(1)

Corner radius tolerance (+/-)

(2)

Cutting depth maximum

(3)

No depth limit

(4)

15