Page 21 - Heat_Exchanger_2020

P. 21

LOGI CHAM

THREE FLUTE 3 CHAMDRILL

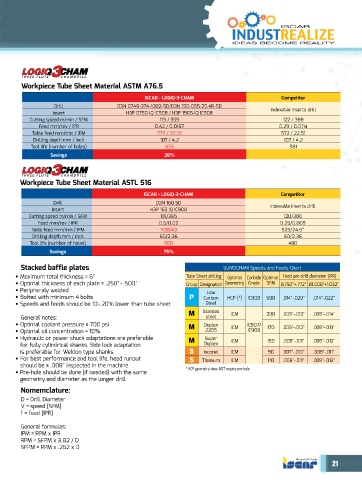

Workpiece Tube Sheet Material ASTM A76.5

ISCAR - LOGIQ-3-CHAM Competitor

Drill D3N 0748-374-1002-5D/D3N 190-095-25.4R-5D

Insert H3P 0750-IQ IC908 / H3P 1905-IQ IC908 Indexable inserts drill

Cutting speed m/min / SFM 113 / 359 122 / 388

Feed mm/rev / IPR 0.42 / 0.0167 0.29 / 0.0114

Table feed mm/min / IPM 775 / 30.51 572 / 22.51

Drilling depth mm / inch 107 / 4.2 107 / 4.2

Tool life (number of holes) 833 581

Savings 26%

LOGI CHAM

THREE FLUTE 3 CHAMDRILL

Workpiece Tube Sheet Material ASTL 516

ISCAR - LOGIQ-3-CHAM Competitor

Drill D3N 160 5D

Insert H3P 163 IQ IC908 Indexable inserts drill

Cutting speed m/min / SFM 115/365 120/380

Feed mm/rev / IPR 0.5/0.02 0.25/0.009

Table feed mm/min / IPM 1100/43 625/24.5”

Drilling depth mm / inch 60/2.36 60/2.36

Tool life (number of holes) 580 480

Savings 75%

Stacked baffle plates SUMOCHAM Speeds and Feeds Chart

• Maximum total thickness = 6" Tube Sheet drilling: Optimal Carbide Optimal Feed per drill diameter (IPR)

• Optimal thickness of each plate = .250"÷.500" Group Designation Geometry Grade SFM Ø.750”÷.772” Ø1.008”÷1.032”

• Peripheraly welded Low

• Bolted with minimum 4 bolts P Carbon HCP (*) IC908 500 .014"-.020" .014"-.022"

• Speeds and feeds should be 10÷20% lower than tube sheet Steel

M Stainles ICM 200 .009"-.013" .009"-.014"

General notes: steel

• Optimal coolant pressure ≥ 700 psi M Duplex ICM IC907/ 170 .008"-.012" .009"-.013"

• Optimal oil concentration = 10% 2205 IC908

• Hydraulic or power chuck adaptations are preferable M Super ICM 150 .008"-.011" .009"-.012"

for fully cylindrical shanks. Side lock adaptation Duplex

is preferable for Weldon type shanks S Inconel ICM 90 .007"-.010" .008"-.011"

• For best performance and tool life, head runout S Titanium ICM 110 .008"-.011" .009"-.012"

should be ≤ .008" inspected in the machine

• Pre-hole should be done (if needed) with the same * HCP geometry does NOT require pre-hole

geometry and diameter as the longer drill

Nomemclature:

D = Drill Diameter

V = speed [SFM]

f = feed [IPR]

General formulas:

IPM = RPM x IPR

RPM = SFPM x 3.82 / D

SFPM = RPM x .262 x D

21