Page 13 - Heat_Exchanger_2020

P. 13

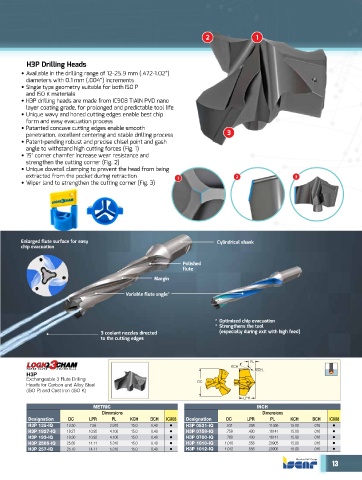

H3P Drilling Heads

• Available in the drilling range of 12-25.9 mm (.472-1.02”)

diameters with 0.1 mm (.004”) increments

• Single type geometry suitable for both ISO P

and ISO K materials

• H3P drilling heads are made from IC908 TiAlN PVD nano

layer coating grade, for prolonged and predictable tool life

• Unique wavy and honed cutting edges enable best chip

form and easy evacuation process

• Patanted concave cutting edges enable smooth

penetration, excellent centering and stable drilling process

• Patent-pending robust and precise chisel point and gash

angle to withstand high cutting forces (Fig. 1)

• 15° corner chamfer increase wear resistance and

strengthen the cutting corner (Fig. 2)

• Unique dovetail clamping to prevent the head from being

extracted from the pocket during retraction

• Wiper land to strengthen the cutting corner (Fig. 3)

Enlarged flute surface for easy Cylindrical shank

chip evacuation

Polished

flute

Margin

Variable flute angle*

* Optimized chip evacuation

* Strengthens the tool

3 coolant nozzles directed (especially during exit with high feed)

to the cutting edges

PL

KCH BCH

H3P

Exchangeable 3 Flute Drilling DC

Heads for Carbon and Alloy Steel

(ISO P) and Cast Iron (ISO K)

LPR

METRIC INCH

Dimensions Dimensions

Designation DC LPR PL KCH BCH IC908 Designation DC LPR PL KCH BCH IC908

H3P 135-IQ 13.50 7.58 2.910 15.0 0.40 • H3P 0531-IQ .531 .298 .11456 15.00 .016 •

H3P 1927-IQ 19.27 10.92 4.100 15.0 0.40 • H3P 0759-IQ .759 .430 .16141 15.00 .016 •

H3P 193-IQ 19.30 10.92 4.100 15.0 0.40 • H3P 0760-IQ .760 .430 .16141 15.00 .016 •

H3P 2565-IQ 25.65 14.11 5.310 15.0 0.40 • H3P 1010-IQ 1.010 .556 .20905 15.00 .016 •

H3P 257-IQ 25.70 14.11 5.310 15.0 0.40 • H3P 1012-IQ 1.012 .556 .20905 15.00 .016 •

13