Page 71 - THREADING CATALOG

P. 71

USER GUIDE

THREAD TURNING

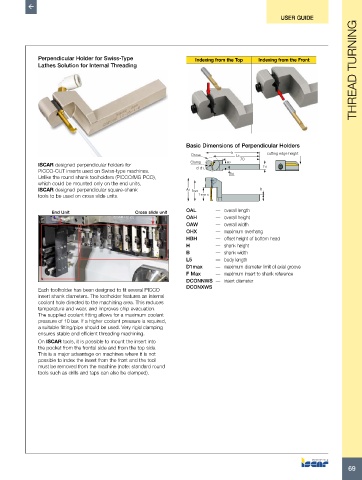

Perpendicular Holder for Swiss-Type Indexing from the Top Indexing from the Front

Lathes Solution for Internal Threading

Basic Dimensions of Perpendicular Holders

l1 cutting edge height

D1max L5

70

ISCAR designed perpendicular holders for Clamp H2 h1

PICCO-CUT inserts used on Swiss-type machines. d-d1 h4

Unlike the round shank toolholders (PICCO/MG PCO),

which could be mounted only on the end units,

ISCAR designed perpendicular square-shank A1 fmax b

tools to be used on cross slide units. Tmax-a

End Unit Cross slide unit OAL — overall length

OAH — overall height

OAW — overall width

OHX — maximum overhang

HBH — offset height of bottom head

H — shank height

B — shank width

L5 — body length

D1max — maximum diameter limit of axial groove

F Max — maximum insert to shank reference

DCONNWS — insert diameter

DCONXWS

Each toolholder has been designed to fit several PICCO

insert shank diameters. The toolholder features an internal

coolant hole directed to the machining area. This reduces

temperature and wear, and improves chip evacuation.

The supplied coolant fitting allows for a maximum coolant

pressure of 10 bar. If a higher coolant pressure is required,

a suitable fitting/pipe should be used. Very rigid clamping

ensures stable and efficient threading machining.

On ISCAR tools, it is possible to mount the insert into

the pocket from the frontal side and from the top side.

This is a major advantage on machines where it is not

possible to index the insert from the front and the tool

must be removed from the machine (note: standard round

tools such as drills and taps can also be clamped).

69