Page 62 - THREADING CATALOG

P. 62

USER GUIDE

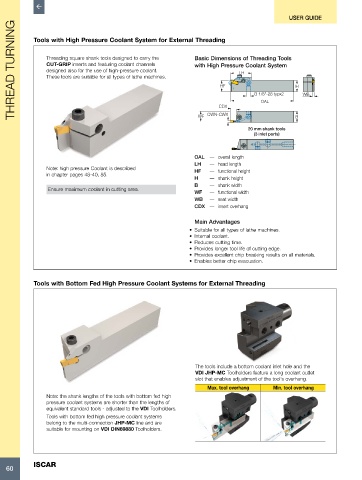

THREAD TURNING Threading square shank tools designed to carry the Basic Dimensions of Threading Tools H WB

Tools with High Pressure Coolant System for External Threading

CUT-GRIP inserts and featuring coolant channels

with High Pressure Coolant System

designed also for the use of high-pressure coolant.

LH

These tools are suitable for all types of lathe machines.

HF

G 1/8"-28 typx2

OAL

CDX

CWN-CWX

WF

20 mm shank tools B

(3 inlet ports)

OAL — overall length

LH — head length

Note: high pressure Coolant is described HF — functional height

in chapter pages 48-40, 85.

H — shank height

B — shank width

Ensure maximum coolant in cutting area.

WF — functional width

WB — seat width

CDX — insert overhang

Main Advantages

• Suitable for all types of lathe machines.

• Internal coolant.

• Reduces cutting time.

• Provides longer tool life of cutting edge.

• Provides excellent chip breaking results on all materials.

• Enables better chip evacuation.

Tools with Bottom Fed High Pressure Coolant Systems for External Threading

The tools include a bottom coolant inlet hole and the

VDI JHP-MC Toolholders feature a long coolant outlet

slot that enables adjustment of the tool’s overhang.

Max. tool overhang Min. tool overhang

Note: the shank lengths of the tools with bottom fed high

pressure coolant systems are shorter than the lengths of

equivalent standard tools - adjusted to the VDI Toolholders.

Tools with bottom fed high pressure coolant systems

belong to the multi-connection JHP-MC line and are

suitable for mounting on VDI DIN69880 Toolholders.

ISCAR

60