Page 287 - THREADING CATALOG

P. 287

USER GUIDE

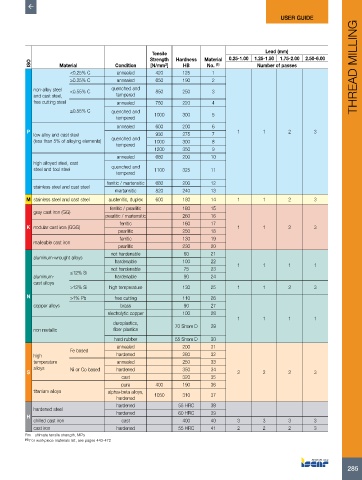

Tensile Lead (mm)

Strength Hardness Material 0.25-1.00 1.25-1.50 1.75-2.00 2.50-6.00

ISO Material Condition [N/mm ] HB No. (1) Number of passes THREAD MILLING

2

<0.25% C annealed 420 125 1

≥0.25% C annealed 650 190 2

non-alloy steel <0.55% C quenched and 850 250 3

and cast steel, tempered

free cutting steel annealed 750 220 4

≥0.55% C quenched and

tempered 1000 300 5

annealed 600 200 6

P 1 1 2 3

low alloy and cast steel 930 275 7

(less than 5% of alloying elements) quenched and 1000 300 8

tempered

1200 350 9

annealed 680 200 10

high alloyed steel, cast

steel and tool steel quenched and 1100 325 11

tempered

ferritic / martensitic 680 200 12

stainless steel and cast steel

martensitic 820 240 13

M stainless steel and cast steel austenitic, duplex 600 180 14 1 1 2 3

ferritic / pearlitic 180 15

gray cast iron (GG)

pearlitic / martensitic 260 16

ferritic 160 17

K nodular cast iron (GGG) 1 1 2 3

pearlitic 250 18

ferritic 130 19

malleable cast iron

pearlitic 230 20

not hardenable 60 21

aluminum-wrought alloys

hardenable 100 22

not hardenable 75 23 1 1 1 1

≤12% Si

aluminum- hardenable 90 24

cast alloys

>12% Si high temperature 130 25 1 1 2 3

N >1% Pb free cutting 110 26

copper alloys brass 90 27

electrolytic copper 100 28

1 1 1 1

duroplastics,

non metallic fiber plastics 70 Shore D 29

hard rubber 55 Shore D 30

annealed 200 31

Fe based

high hardened 280 32

temperature annealed 250 33

alloys Ni or Co based hardened 350 34

S 2 2 2 3

cast 320 35

pure 400 190 36

titanium alloys alpha+beta alloys,

hardened 1050 310 37

hardened 55 HRC 38

hardened steel

H hardened 60 HRC 39

chilled cast iron cast 400 40 3 3 3 3

cast iron hardened 55 HRC 41 2 2 2 3

Rm - ultimate tensile strength, MPa

(1) For workpiece materials list, see pages 443-472

285