Page 281 - THREADING CATALOG

P. 281

USER GUIDE

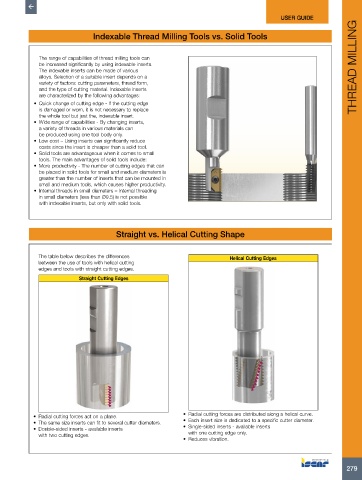

Indexable Thread Milling Tools vs. Solid Tools

The range of capabilities of thread milling tools can

be increased significantly by using indexable inserts.

The indexable inserts can be made of various THREAD MILLING

alloys. Selection of a suitable insert depends on a

variety of factors: cutting parameters, thread form,

and the type of cutting material. Indexable inserts

are characterized by the following advantages:

• Quick change of cutting edge - If the cutting edge

is damaged or worn, it is not necessary to replace

the whole tool but just the, indexable insert.

• Wide range of capabilities - By changing inserts,

a variety of threads in various materials can

be produced using one tool body only.

• Low cost – Using inserts can significantly reduce

costs since the insert is cheaper than a solid tool.

• Solid tools are advantageous when it comes to small

tools. The main advantages of solid tools include:

• More productivity - The number of cutting edges that can

be placed in solid tools for small and medium diameters is

greater than the number of inserts that can be mounted in

small and medium tools, which causes higher productivity.

• Internal threads in small diameters – Internal threading

in small diameters (less than Ø9.5) is not possible

with indexable inserts, but only with solid tools.

Straight vs. Helical Cutting Shape

The table below describes the differences Helical Cutting Edges

between the use of tools with helical cutting

edges and tools with straight cutting edges.

Straight Cutting Edges

• Radial cutting forces act on a plane. • Radial cutting forces are distributed along a helical curve.

• The same size inserts can fit to several cutter diameters. • Each insert size is dedicated to a specific cutter diameter.

• Double-sided inserts - available inserts • Single-sided inserts - available inserts

with two cutting edges. with one cutting edge only.

• Reduces vibration.

279