Page 28 - THREADING CATALOG

P. 28

THREAD TURNING The parameter for tilting the threading insert relative to the helix angle of threading is of great importance when threading

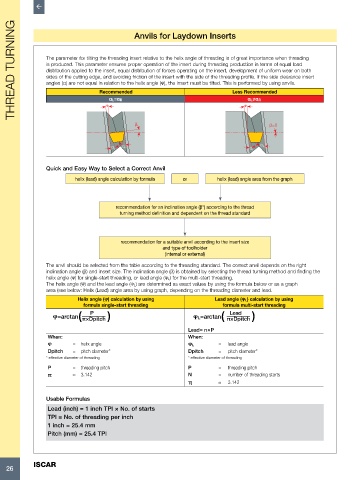

Anvils for Laydown Inserts

is produced. This parameter ensures proper operation of the insert during threading production in terms of equal load

distribution applied to the insert, equal distribution of forces operating on the insert, development of uniform wear on both

sides of the cutting edge, and avoiding friction of the insert with the side of the threading profile. If the side clearance insert

angles (α) are not equal in relation to the helix angle (φ), the insert must be tilted. This is performed by using anvils.

Less Recommended

Recommended

αL=αR

φ

β φ αL≠αR β =0

α R

α R

α L

α L

Quick and Easy Way to Select a Correct Anvil

helix (lead) angle calculation by formula or helix (lead) angle area from the graph

recommendation for an inclination angle (β°) according to the thread

turning method definition and dependent on the thread standard

recommendation for a suitable anvil according to the insert size

and type of toolholder

(internal or external)

The anvil should be selected from the table according to the threading standard. The correct anvil depends on the right

inclination angle (β) and insert size. The inclination angle (β) is obtained by selecting the thread turning method and finding the

helix angle (φ) for single-start threading, or lead angle (φ L) for the multi-start threading.

The helix angle (φ) and the lead angle (φ L) are determined as exact values by using the formula below or as a graph

area (see below: Helix (Lead) angle area by using graph, depending on the threading diameter and lead.

Helix angle (φ) calculation by using Lead angle (φ L) calculation by using

formula single-start threading formula multi-start threading

( π×Dpitch ) π×Dpitch )

Lead

P

φ=arctan φ =arctan (

L

Lead= n×P

When: When:

φ = helix angle φ L = lead angle

Dpitch = pitch diameter* Dpitch = pitch diameter*

* effective diameter of threading * effective diameter of threading

P = threading pitch P = threading pitch

π ≈ 3.142 N = number of threading starts

π ≈ 3.142

Usable Formulas

Lead (inch) = 1 inch TPI × No. of starts

TPI = No. of threading per inch

1 inch = 25.4 mm

Pitch (mm) = 25.4 TPI

ISCAR

26