Page 14 - USER_GUIDE_WhisperLine

P. 14

USER GUIDE - WHISPERLINE VIBRATION - DAMPING TURNING BLADES FOR LATHE MACHINES

User Guide

• RPM is one of the most important factors that affect vibrations. To maintain a

stable and controlled machining process, use constant RPM (G97).

• Each blade is pre-calibrated in laboratory conditions for an overhang of 100mm (3.94").

• Although the pre-calibration is suitable for a wide range of overhangs, sometimes fine-tuning

calibration is necessary, depending on the overhang and clamping rigidity of the machine.

• Before making fine tuning calibration, try to optimize the cutting conditions.

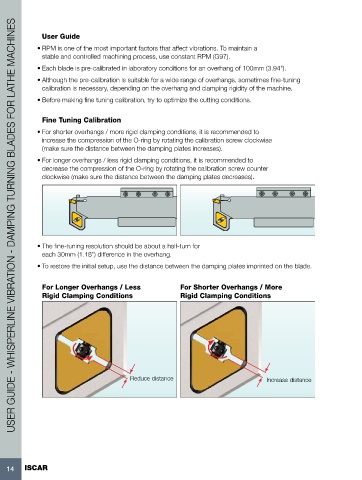

Fine Tuning Calibration

• For shorter overhangs / more rigid clamping conditions, it is recommended to

increase the compression of the O-ring by rotating the calibration screw clockwise

(make sure the distance between the damping plates increases).

• For longer overhangs / less rigid clamping conditions, it is recommended to

decrease the compression of the O-ring by rotating the calibration screw counter

clockwise (make sure the distance between the damping plates decreases).

• The fine-tuning resolution should be about a half-turn for

each 30mm (1.18") difference in the overhang.

• To restore the initial setup, use the distance between the damping plates imprinted on the blade.

For Longer Overhangs / Less For Shorter Overhangs / More

Rigid Clamping Conditions Rigid Clamping Conditions

Reduce distance Increase distance

14 ISCAR