Page 168 - ISCAR FACE GROOVING LINES

P. 168

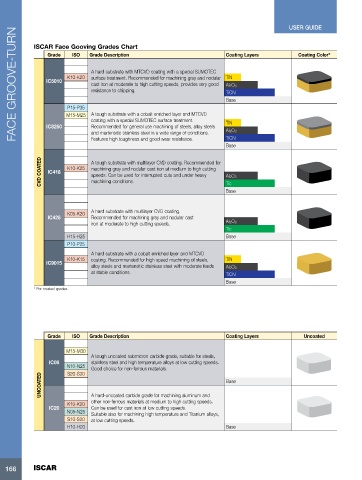

FACE GROOVE-TURN ISCAR Face Gooving Grades Chart Coating Layers USER GUIDE

CVD COATED Grade ISO Grade Description Coating Color*

IC5010 K10-K20 A hard substrate with MTCVD coating with a special SUMOTEC TiN

surface treatment. Recommended for machining gray and nodular Al2O3

P15-P35 cast iron at moderate to high cutting speeds, provides very good TiCN

M15-M25 resistance to chipping. Base

IC8250

A tough substrate with a cobalt enriched layer and MTCVD TiN

coating with a special SUMOTEC surface treatment. Al2O3

Recommended for general use machining of steels, alloy steels TiCN

and martensitic stainless steel in a wide range of conditions. Base

Features high toughness and good wear resistance.

IC418 K10-K25 A tough substrate with multilayer CVD coating. Recommended for

machining gray and nodular cast iron at medium to high cutting

speeds. Can be used for interrupted cuts and under heavy Al2O3

machining conditions. Tic

Base

IC428 K05-K20 A hard substrate with multilayer CVD coating.

Recommended for machining gray and nodular cast

iron at moderate to high cutting speeds. Al2O3

Tic

IC9015 H15-H25 A hard substrate with a cobalt enriched layer and MTCVD Base

P10-P25 coating. Recommended for high speed machining of steels,

alloy steels and martensitic stainless steel with moderate feeds TiN

K10-K15 at stable conditions. Al2O3

TiCN

Base

* For coated grades

Grade ISO Grade Description Coating Layers Uncoated

IC08 M15-M30 A tough uncoated submicron carbide grade, suitable for steels,

stainless steel and high temperature alloys at low cutting speeds.

N10-N25 Good choice for non-ferrous materials.

S20-S30

UNCOATED

Base

IC20 K10-K20 A hard-uncoated carbide grade for machining aluminum and

N05-N25 other non-ferrous materials at medium to high cutting speeds.

S10-S20 Can be used for cast iron at low cutting speeds.

H10-H20 Suitable also for machining high temperature and Titanium alloys,

at low cutting speeds.

Base

166 ISCAR