Page 29 - notch_grip_2021

P. 29

GAN INSL MeasuMreemtreicnts

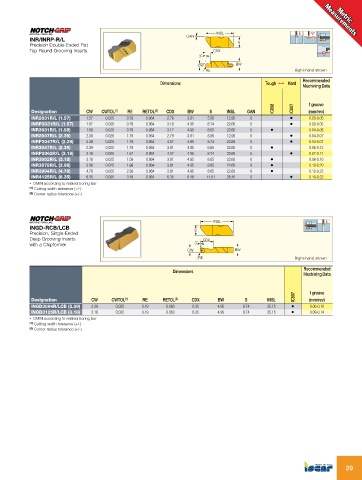

INR/INRP-R/L CDX S

Precision Double-Ended Flat 3˚ BW

Top Round Grooving Inserts

CW

RE Right-hand shown

Dimensions Tough 1 Hard Recommended

Machining Data

IC808 f groove

IC807

Designation CW CWTOL(1) RE RETOL(2) CDX BW S INSL GAN (mm/rev)

• 0.03-0.05

INR2031R/L (1.57) 1.57 0.025 0.78 0.064 2.79 3.81 5.56 12.95 0 • 0.03-0.05

INRP3031R/L (1.57) 1.57 0.025 0.78 0.064 3.18 4.95 8.74 22.60 5 •

INR3031R/L (1.58) 1.58 0.025 0.79 0.064 3.17 4.95 8.65 22.60 0 0.04-0.08

• 0.04-0.07

INR2047R/L (2.39) 2.39 0.025 1.19 0.064 2.79 3.81 5.56 12.95 0 • 0.04-0.07

INRP3047R/L (2.39) 2.39 0.025 1.19 0.064 4.57 4.95 8.74 22.60 5 •

INR3047R/L (2.39) 2.39 0.025 1.19 0.064 3.81 4.95 8.65 22.60 0 0.06-0.12

• 0.07-0.11

INRP3062R/L (3.18) 3.18 0.025 1.57 0.064 4.57 4.95 8.74 22.60 5 •

INR3062R/L (3.18) 3.18 0.025 1.59 0.064 3.81 4.95 8.65 22.60 0 • 0.08-0.16

INR3078R/L (3.98) 3.96 0.025 1.98 0.064 3.81 4.95 8.65 22.60 0 • 0.10-0.20

INR3094R/L (4.78) 4.78 0.025 2.39 0.064 3.81 4.95 8.65 22.60 0 0.12-0.22

• 0.10-0.22

INR4125R/L (6.35) 6.35 0.025 3.18 0.064 6.35 6.48 11.51 28.45 0

• DMIN according to related boring bar

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

INGD-RCB/LCB INSL

Precision, Single-Ended S

Deep Grooving Inserts 3˚ CDX

with a Chipformer CW

RE BW

Dimensions Right-hand shown

Designation CW CWTOL(1) RE RETOL(2) CDX BW S RecommendedIC807

Machining Data

INGD3094R/LCB (2.39) 2.39 0.025 0.19 0.063 6.35 4.95 8.74

f groove

INGD3125R/LCB (3.18) 3.18 0.025 0.19 0.063 6.35 4.95 8.74 INSL (mm/rev)

25.15 • 0.06-0.10

25.15 • 0.09-0.14

• DMIN according to related boring bar

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

29